LORELEI

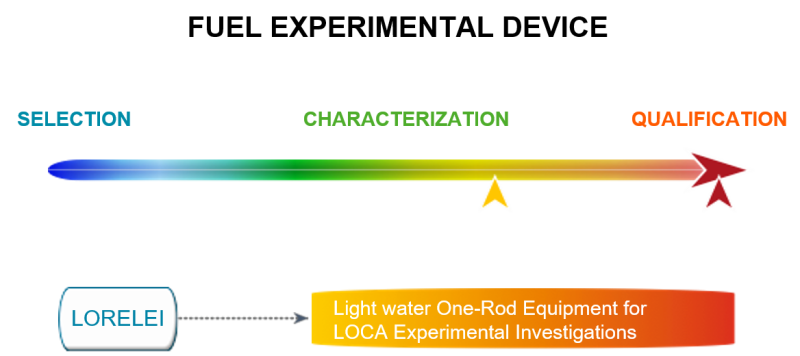

The LORELEI experimental device is designed to characterise new cladding materials, fuel materials, fuel assembly designs, fuel management strategies (high burn-up, high duty) and the corresponding fission product releases in LOCA conditions. Experiments will focus on the thermomechanical behaviour of the fuel rod: ballooning and clad burst with possible fuel relocation both inside and outside the rod, corrosion at high temperature, oxidation, hydriding and resulting cladding embrittlement, quenching and post-quench behaviour in terms of mechanical strength. An objective is also to quantify fission product releases thanks to the analysis of contaminated liquid and gas samples.

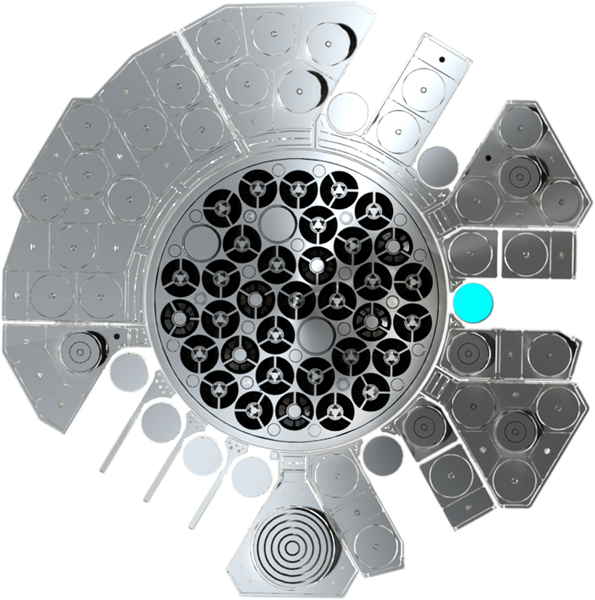

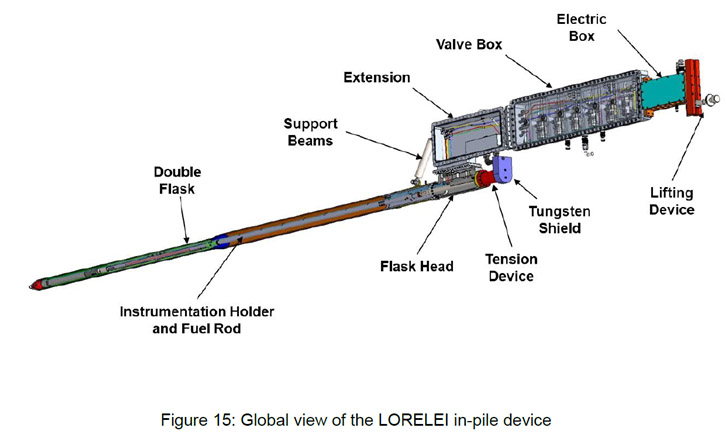

The LORELEI experimental device will be placed in the JHR Material Test Reactor reflector. The power level is therefore controlled by varying the distance between the sample and the core vessel. It will be connected to a specific cubicle (to ensure initial configuration) in order to control draining and re-filling phases. It will also be connected to the fission product laboratory where all the contaminated fluids will be transferred, analysed and partly sampled at the end of the test. One sampling line located at the bottom of the device will be used for water and another sampling line at the top of the vessel will be used for gas.

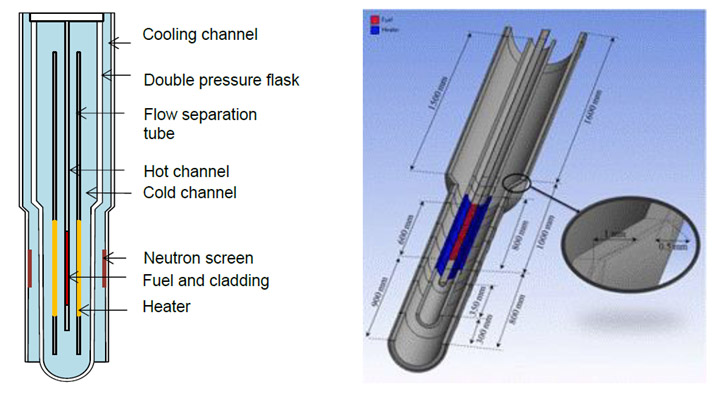

To avoid azimuthal temperature differences and to simulate adiabatic conditions, a peripheral electrical heat exchanger will be implemented like a shell around the fuel. The azimuthal cladding temperature difference is expected to be less than 10°C.

The peripheral heat exchanger is stopped at high temperature (i.e. after clad burst or when 900°C is reached) in order to increase apparent heat losses from the rod and thereby avoid steam-Zircaloy thermal escalation.

A neutron screen will be installed to flatten the axial power profile (maximum length of 40 cm) and ensure the power distribution. During the dry phase, a small amount of water will be maintained at the bottom of the device to provide a saturated ‘steam atmosphere’, with the steam being generated by a specific electrical heater. A debris catcher fitted near the bottom of the device will retrieve fuel particles without hindering steam generation.

The initial internal pressure of the fuel sample is a test parameter that can be adjusted while preparing the sample before every experiment, according to on the expected ballooning and burst conditions.

Instrumentation will be installed to monitor the temperature and pressure in different parts of the device and at each step of the experimental sequence. The axial displace at the top of the fuel sample holder will also be measured. Based on the displacement measurements and thermal displacement computations, sample elongation can be estimated.

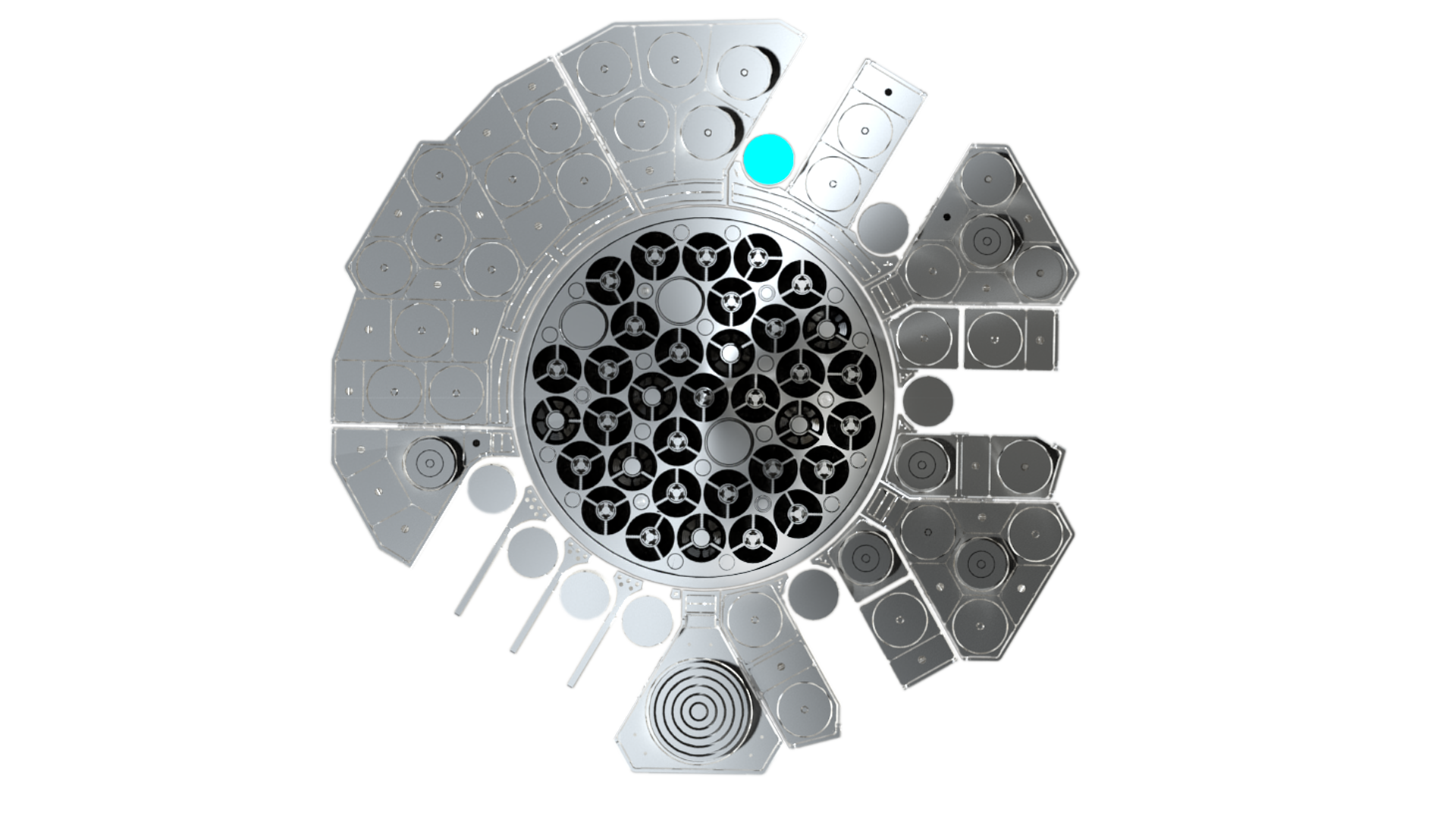

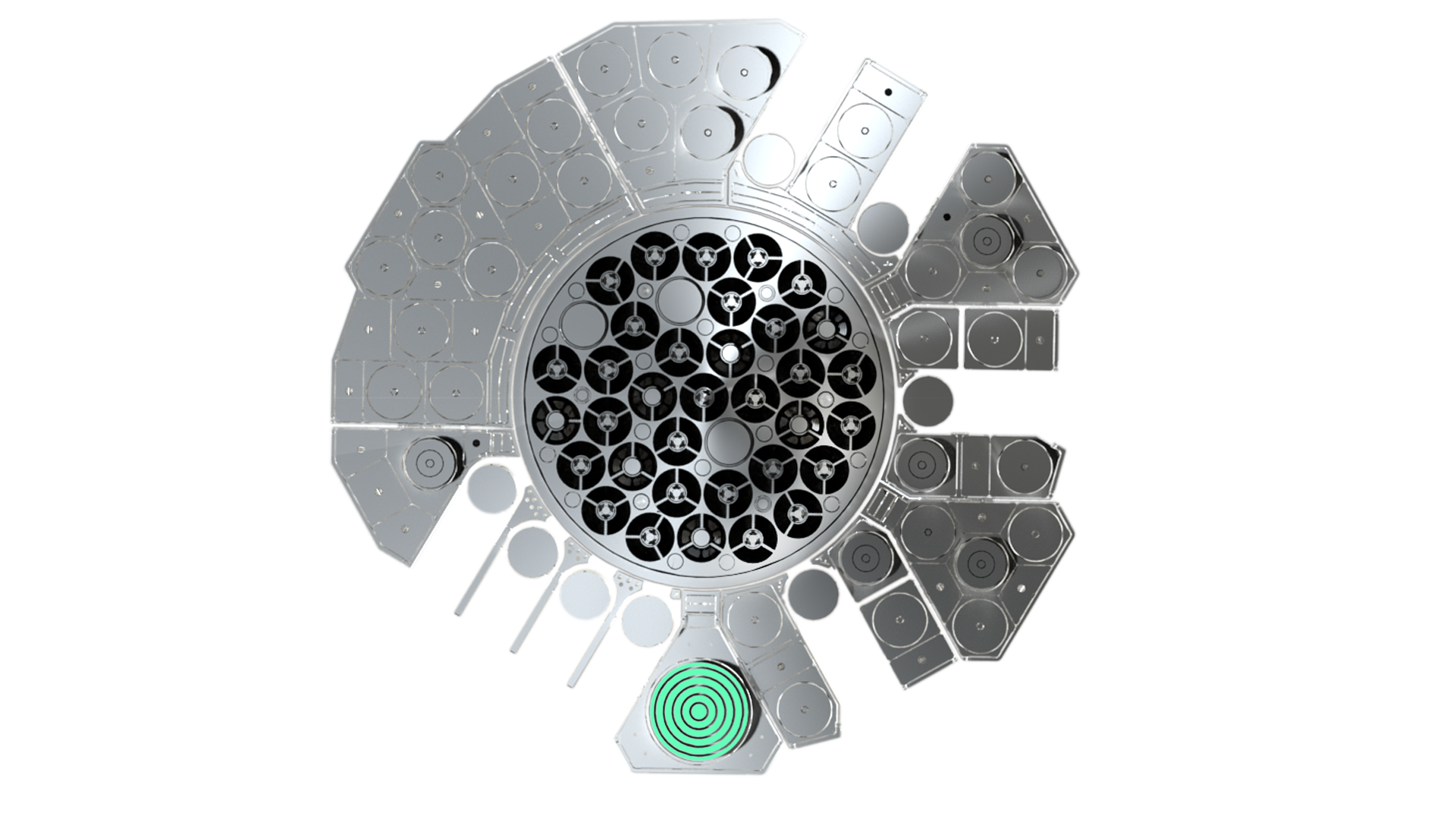

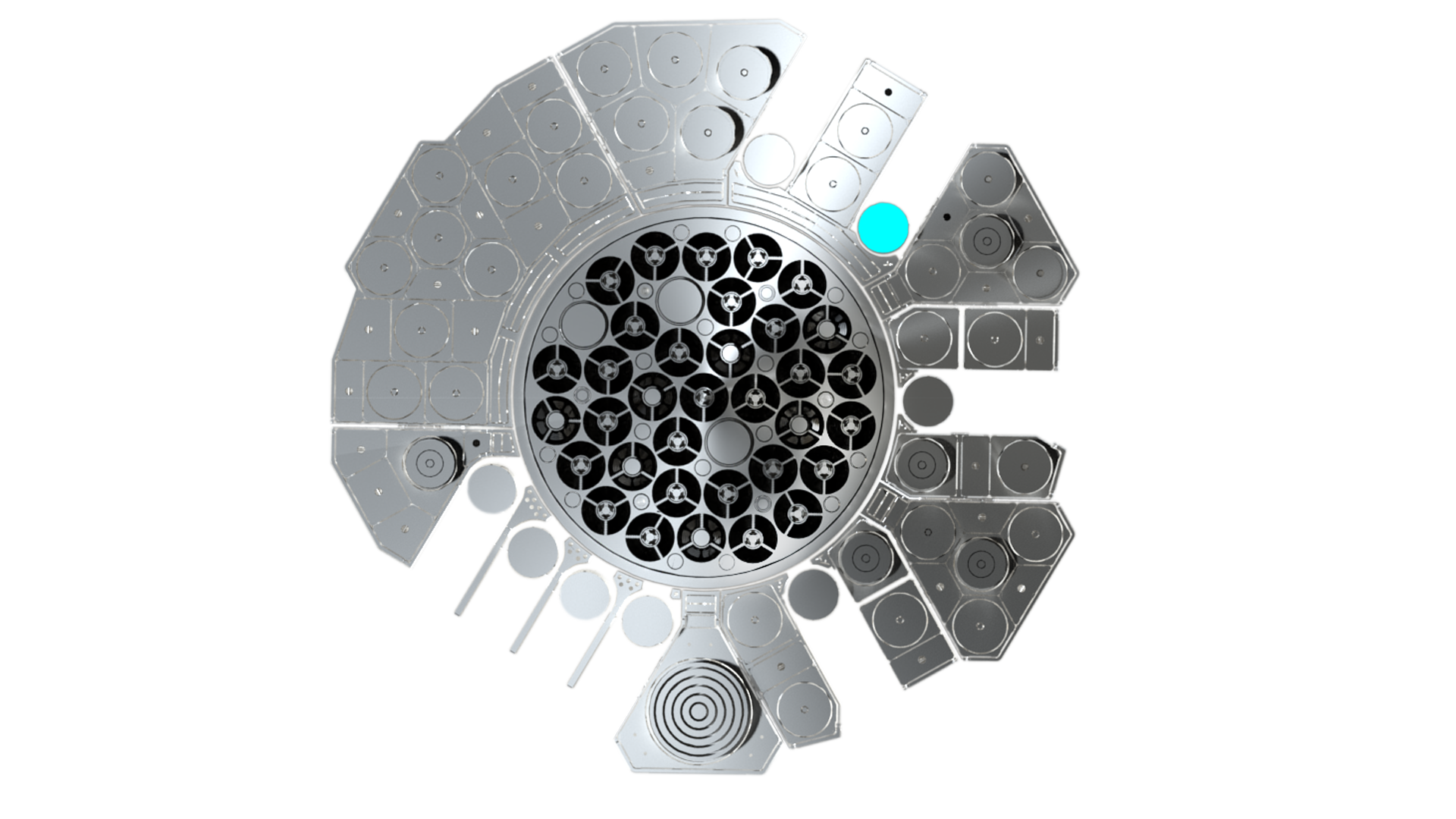

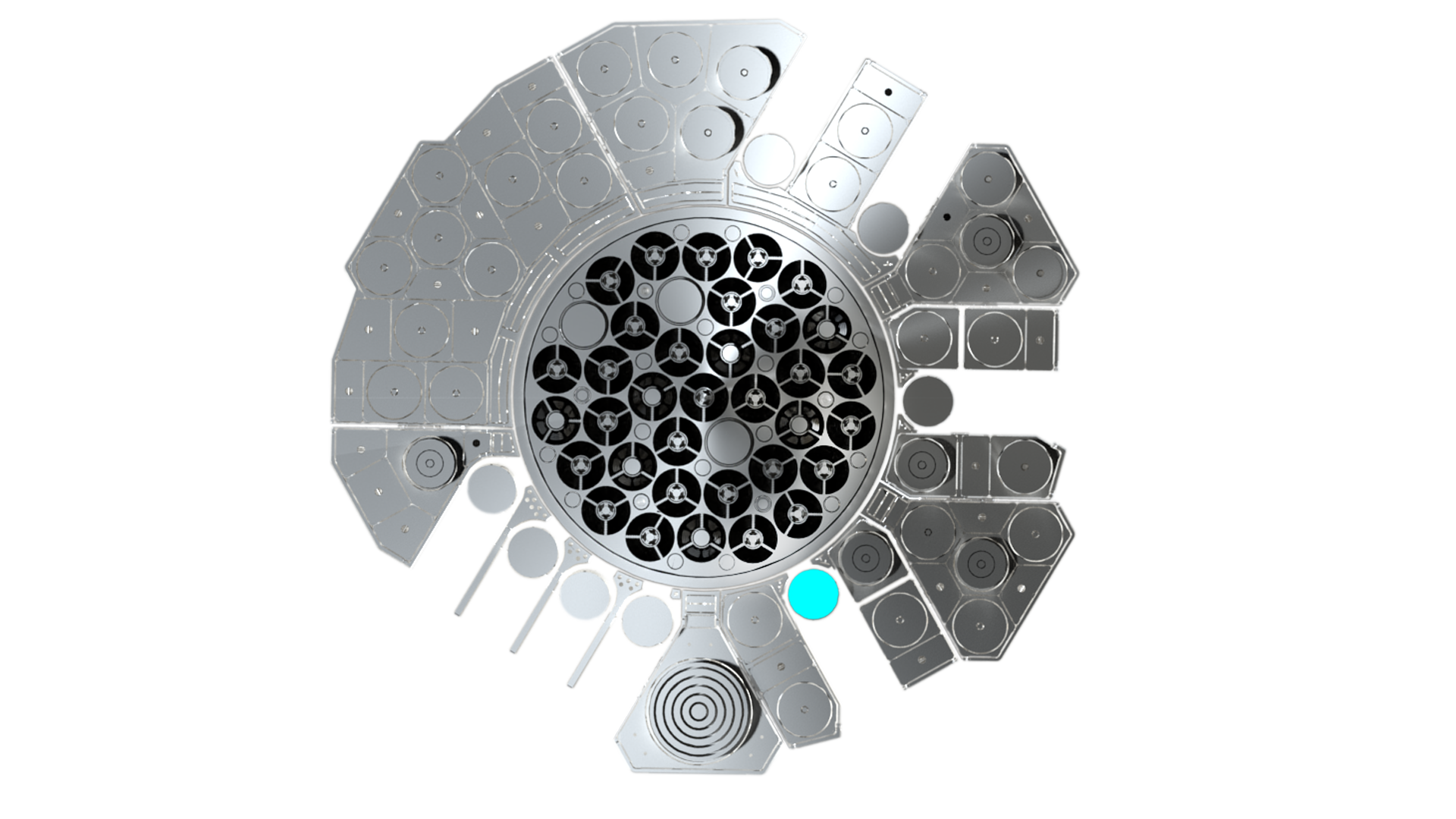

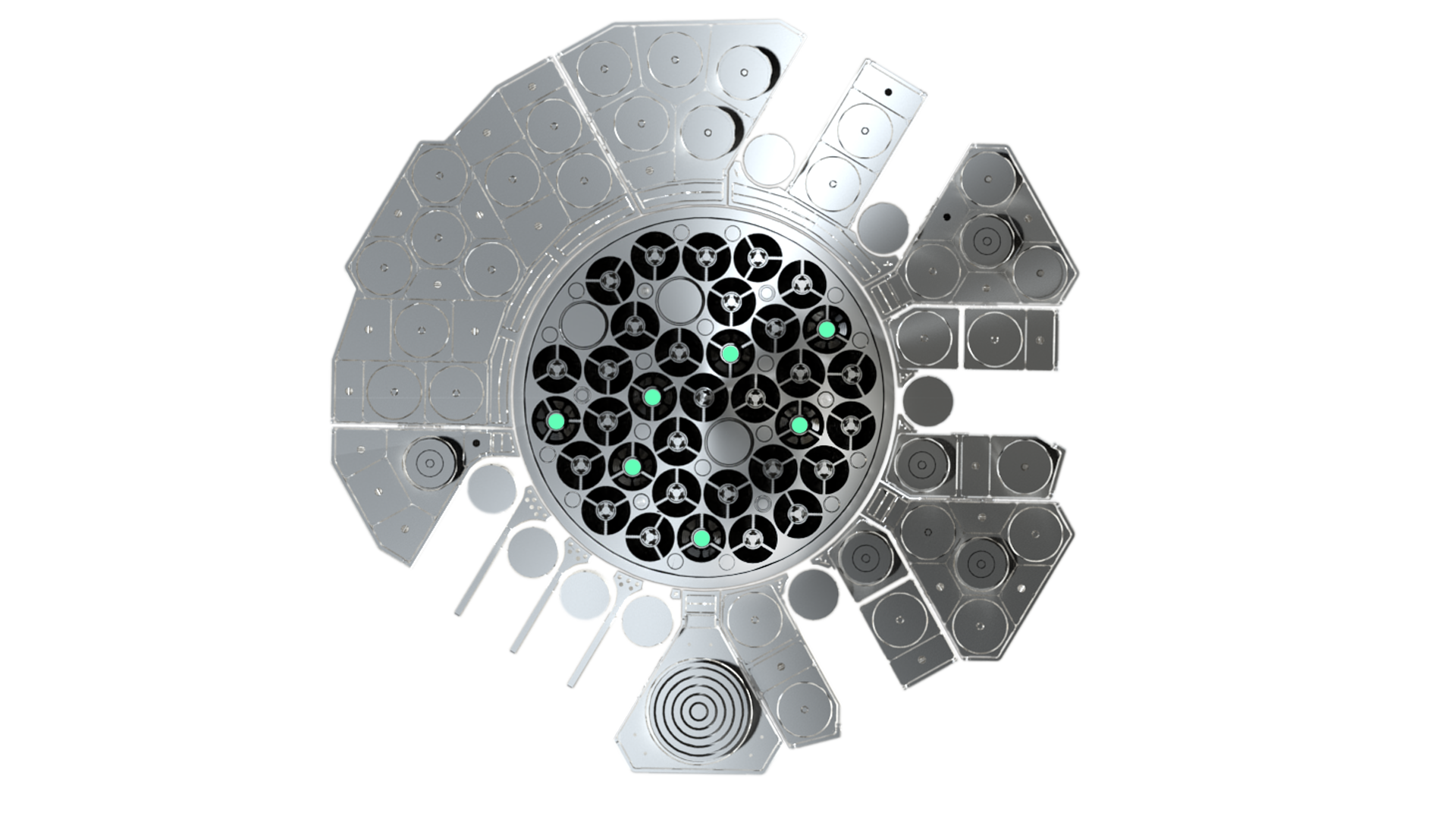

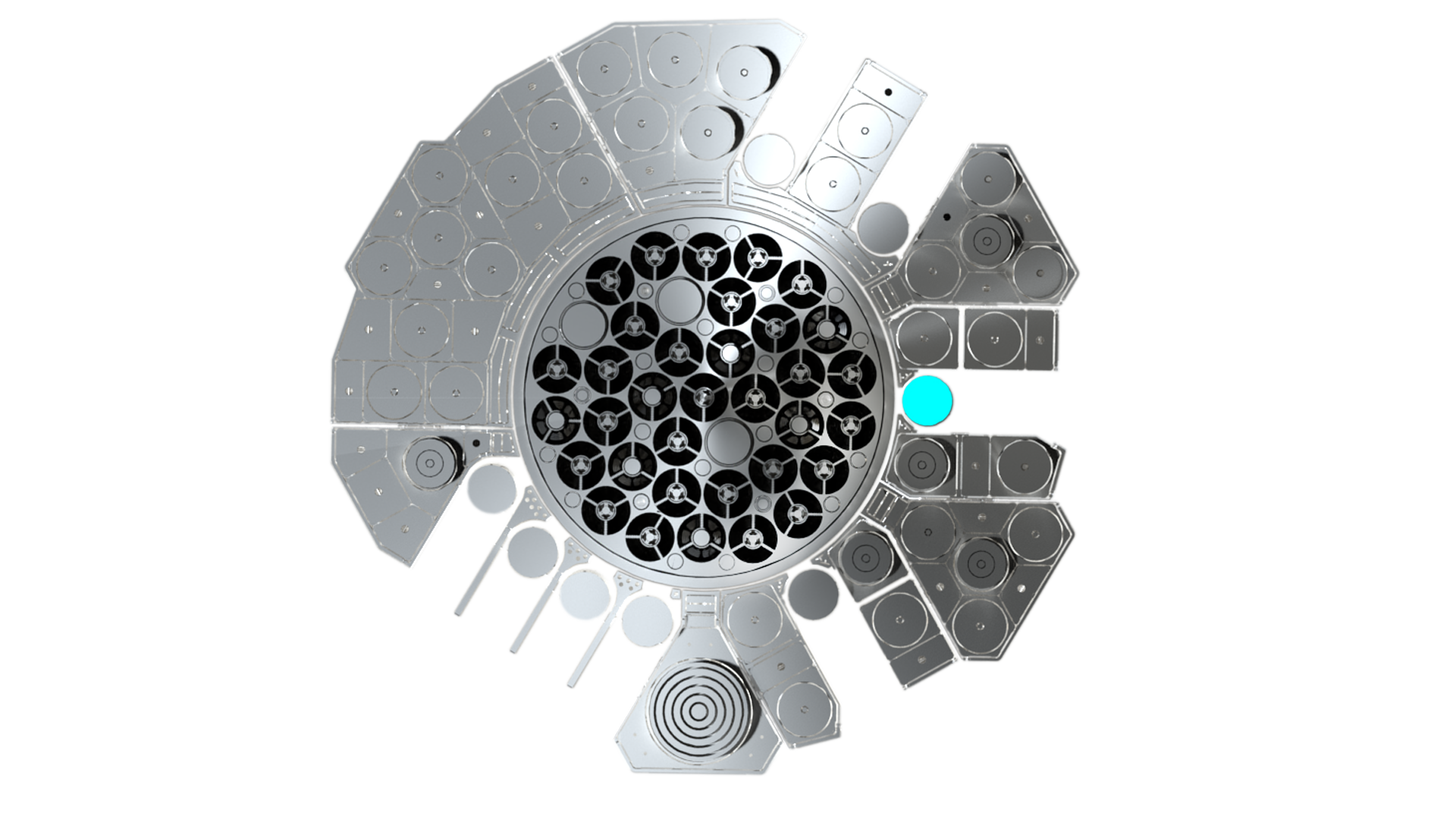

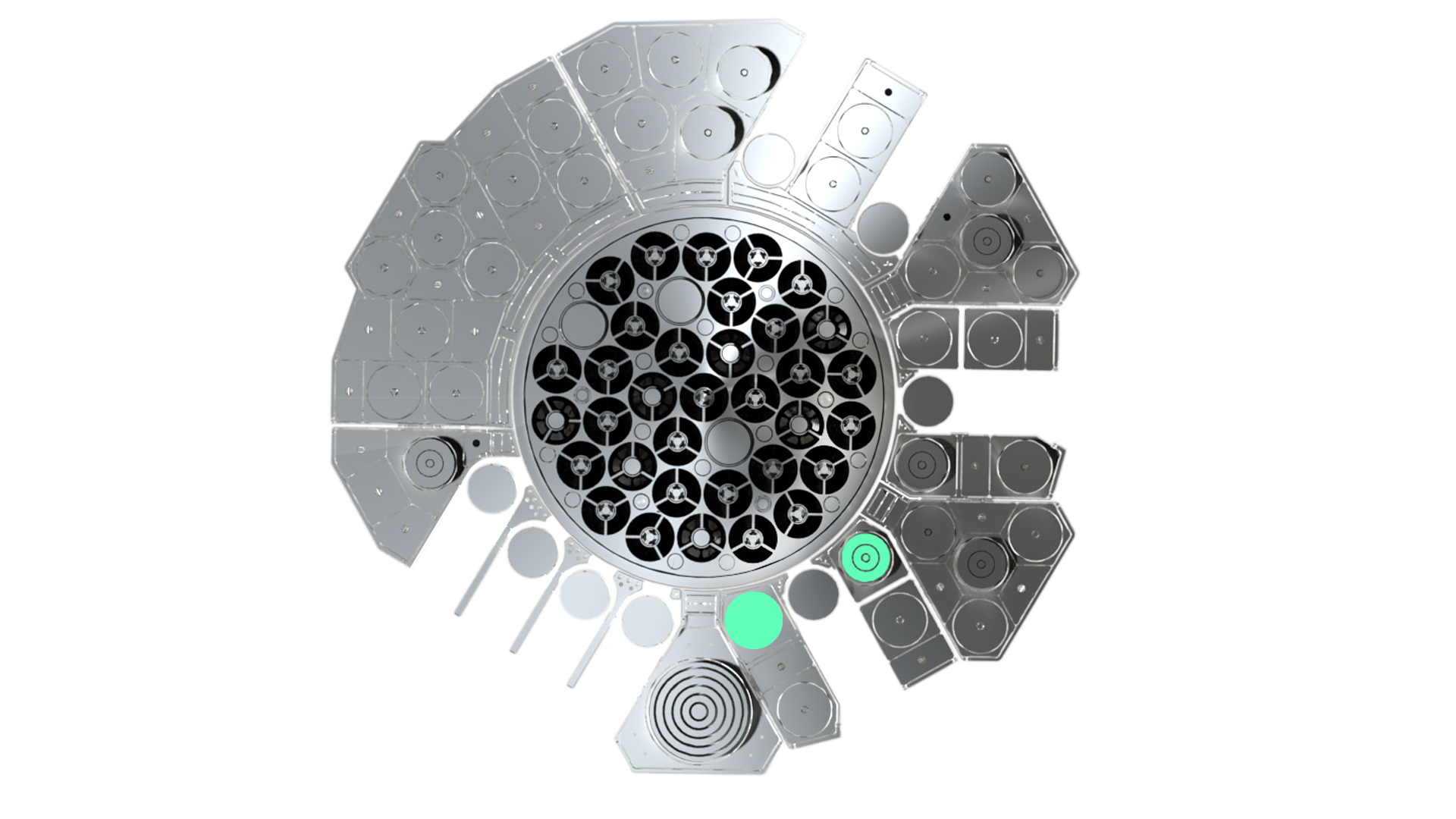

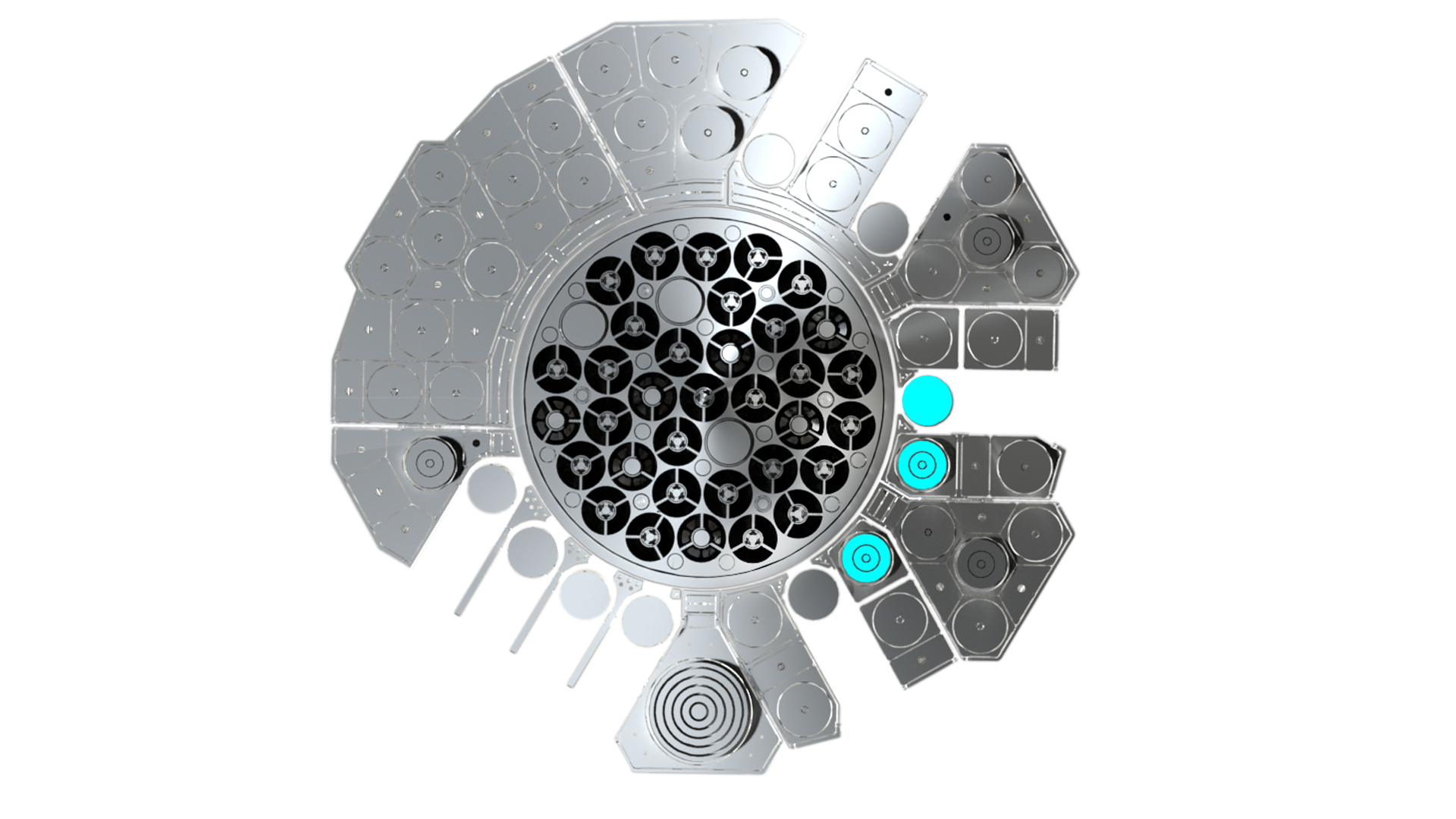

A general view of LORELEI in-core parts is provided here below.

The JHR has been designed with a full set

of experimental devices making

it possible to conduct the experiments

needed to characterise,

select and qualify new fuels and materials.

Some of these experimental devices

are capsules while others are loops,

which makes it possible to adjust

the experimental conditions in real time

to obtain even better results.