Operational phase

The JHR Material Test Reactor is currently in its construction phase, but the future JHR Material Test Reactor operating teams are already preparing to start up the reactor, i.e. achieving first criticality. This preparatory phase and the future operation of the JHR Material Test Reactor are briefly described below.

Transitioning to operation

Equipment will be handed over to the future operator progressively.

The future operator will progressively take over operation of the equipment as the acceptance tests and procedures are completed by contractors. Once the necessary tests have been performed on entire systems potentially involving equipment supplied by different contractors, the operator can finalise acceptance and officially becomes the operator.

The future operator will therefore be responsible for operating the equipment, managing spare parts, ensuring maintenance and completing regulatory checks. The CEA Cadarache centre’s support services will provide JHR Material Test Reactor with support during this phase; this may require implementing specific contracts for the maintenance of certain equipment (reactivity control mechanisms, primary pumps, etc).

Following on from this, the future operator will then take part in the global and integration tests, working with the Project Test team until taking over full responsibility as nuclear operator for delivery of the nuclear fuel.

OPERATING SCHEDULE

The JHR Material Test Reactor will be managing in line with 4-year plans, known as ” ROPs “.

This ROP corresponds to the transition between qualification of the machine and experimental tools and the ‘industrial’ production phase, i.e. when the reactor reaches nominal power so the devices can be implemented for this first set of experiments.

The reactor will first be tested at 70 MW and then 100 MW before the devices for the first set of experiments can be tested and qualified; production will then be ramped up.

This ROP corresponds to an optimal production phase with installation of devices for the second set of experiments.

This ROP corresponds to the implementation of the third set of experimental devices and nominal production of devices from the first and second sets of experiments. The progress made in the development of devices and production capacities for the first two ROPs is summarised here below.

OPERATING SCHEDULE

The JHR Material Test Reactor will be managing in line with 4-year plans, known as ROPs.

This ROP corresponds to the transition between qualification of the machine and experimental tools and the ‘industrial’ production phase, i.e. when the reactor reaches nominal power so the devices can be implemented for this first set of experiments.

The reactor will first be tested at 70 MW and then 100 MW before the devices for the first set of experiments can be tested and qualified; production will then be ramped up.

This ROP corresponds to an optimal production phase with installation of devices for the second set of experiments.

This ROP corresponds to the implementation of the third set of experimental devices and nominal production of devices from the first and second sets of experiments. The progress made in the development of devices and production capacities for the first two ROPs is summarised here below.

UNIT RESPONSIBLE

FOR REACTOR OPERATIONS

UNIT RESPONSIBLE FOR REACTOR OPERATIONS

Role and mission statement

The unit in charge of reactor operations will manage the JHR Material Test Reactor, carry out periodic inspections and tests, regulatory periodic checks and JHR Material Test Reactor equipment maintenance. It will also complete all tasks related to running the facility (scheduling, training, nuclear waste management, radioactive source management, transportation, waste, effluents, environment, fuel fabrication monitoring, cycle calculations, document tracking, etc.

Organisation

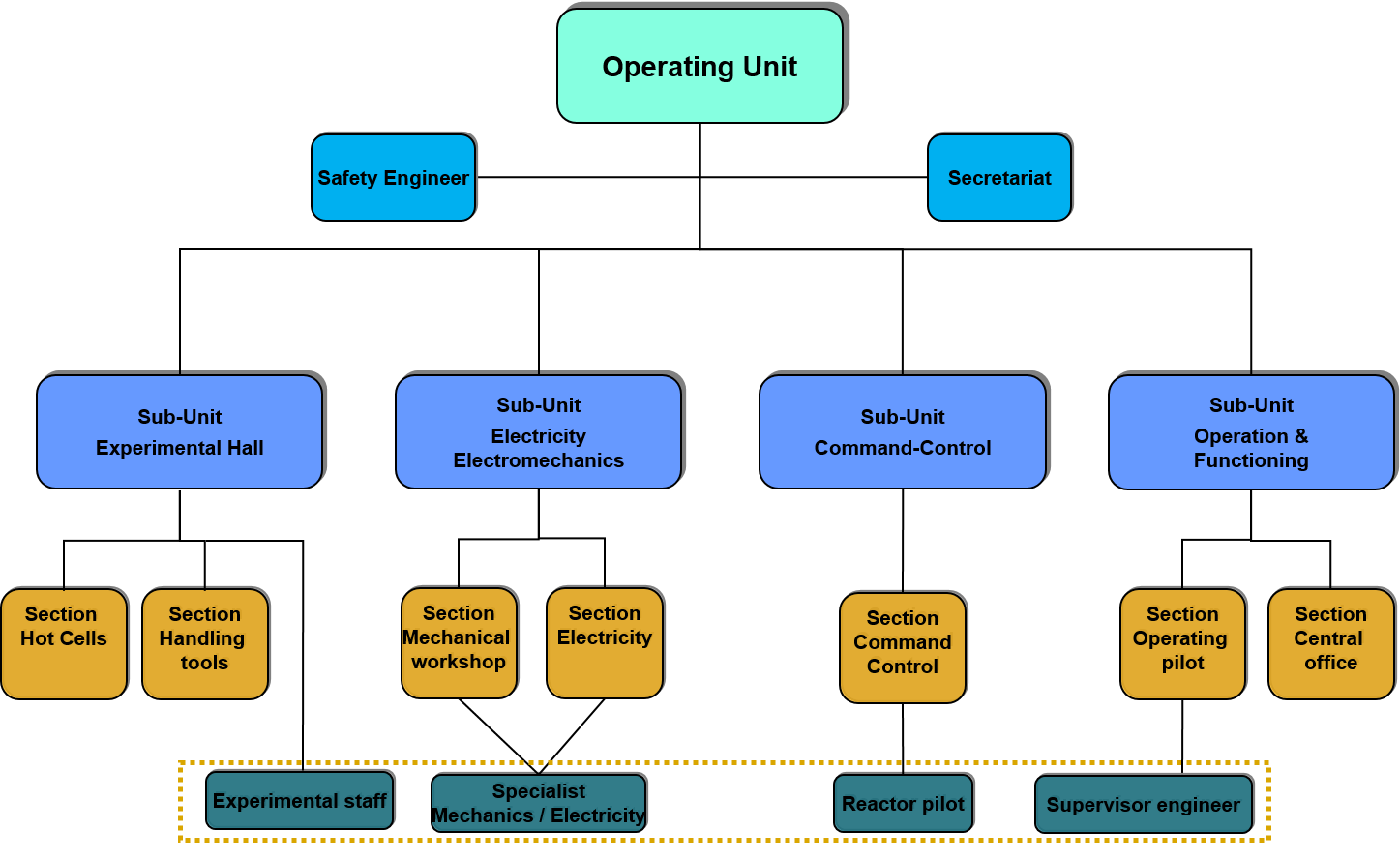

The reactor operations unit is divided into four sub-units:

⦁ Hall-Experimentation- hot cell

⦁ Mechanical, Electrical and HVAC (MEH)

⦁ I&C systems

⦁ Operations section in which the Central Operating Office is responsible for administrative tasks regarding operations

The sub-units are organised in technical groups, including the day shift teams who are responsible for carrying out operational tasks (or their preparation), maintenance and tests.

Reactor operations are ensured by teams

The reactor will be run by six teams with 5 operators each; there will be three 8-hour shifts (day shift, swing shift and night shift) to ensure continuous operation. Each of the 6 shift teams will have:

⦁ Shift manager

⦁ Reactor control room operator

⦁ Expert in electrical engineering

⦁ Expert in mechanical engineering

⦁ Shift experimenter.

Technical professions

The technical specialities required to operate the JHR are:

⦁ hot cell operator (remote handing),

⦁ Operator for maintenance in air and under water (qualified to handle nuclear fuel, experimental devices and other objects),

⦁ Mechanical technician responsible for the operation of JHR Material Test Reactor mechanical systems and equipment, work in hot or cold workshops, performing operations on JHR Material Test Reactor mechanical components and systems; this person must also be qualified for mechanical isolations,

⦁ Electrician responsible for the operation of all automated and centralised I&C systems in the facility. This person will also be in charge of the control room simulator and the 3D room.

UNIT RESPONSIBLE FOR EXPERIMENTAL DEVICE OPERATIONS

UNIT RESPONSIBLE FOR EXPERIMENTAL DEVICE OPERATIONS

Role and mission statement

This unit is responsible for operating the experimental devices and non-destructive test benches. Its organisation will be adapted according to the number of experiments to operate at a time (concept of experimental load).

This unit will also support JHR Material Test Reactor activities when preparing for experiments: hydraulic benches, mock-up cells, specific operations, etc.

Organisation

The experimental device operations unit is divided into two sub-units:

– The first is responsible for the experiments (preparation and assembly in the Assembly Building (BMM), in cold and hot cells, operations at pool workstations, and expertise in non-destructive test benches)

– The second provides support (calculations, implementation of non-destructive test benches, dosimeters, data acquisition and providing clients with results).

Technical professions

The jobs required in the experimental device operations service are:

⦁ Technical experimenters to perform operations related to the experiments (connections, fluid transfers, checks, leakage tests, etc.) and maintenance on circuits in experimental cubicles and the reactor pool environment (or on a support basis)

⦁ Engineers to oversee the work of technical experimenters in coordination with the reactor’s operating team

⦁ Engineers and technicians specialised in neutron calculations, thermohydraulics, nuclear physics, instrumentation, databases and data interfaces with clients, etc.

A TYPICAL DAY AN EXPERIMENTAL DEVICE OPERATOR

INVOLVES THE FOLLOWING TASKS

A TYPICAL DAY AN EXPERIMENTAL DEVICE OPERATOR

INVOLVES THE FOLLOWING TASKS

MAINTENANCE AND

WASTE MANAGEMENT

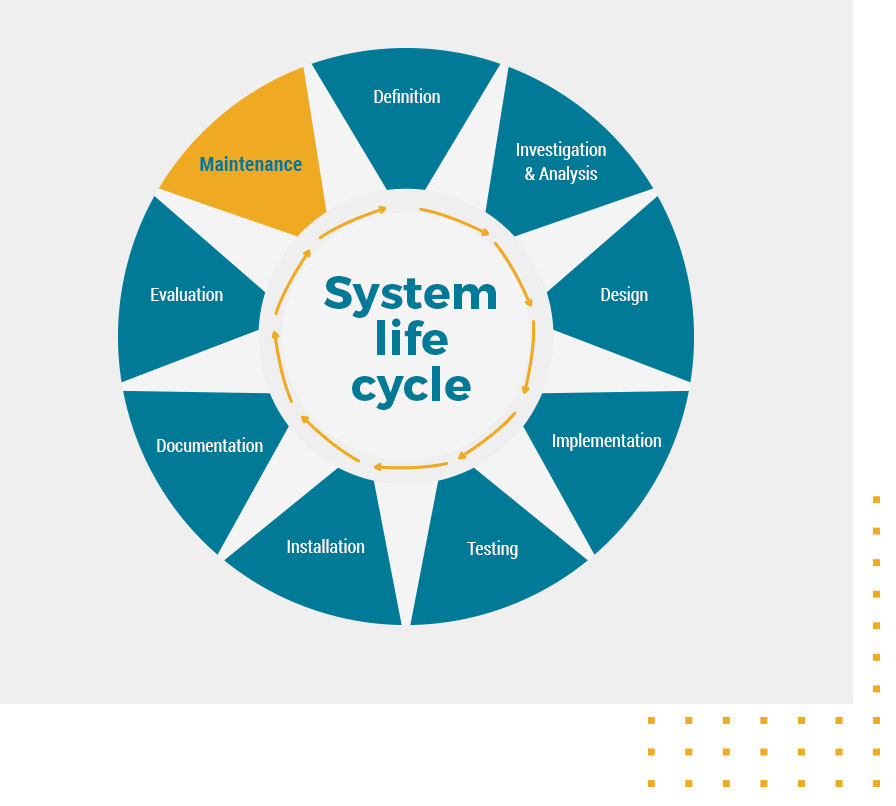

Maintenance

These operations are required to keep the equipment in good working order. Their frequency depends on the equipment’s reliability and their level of importance to nuclear safety. In compliance with the French nuclear pressure equipment (ESPN) decree, certain pressure equipment must be inspected periodically, such as the primary system. Finally, it is also necessary to conduct periodic tests and inspections to check the availability of safety functions, particularly those ensuring back-up functions needed in the case of accident conditions.

The reactor cycles will last 25 to 36 days, alternating with inter-cycle periods to partially reload the fuel (one fourth each time) and rearrange the core. A long outage will also be planned every year to conduct maintenance operations, periodic regulatory checks, and all periodic tests and inspections of all systems.

Optimisation of reactor availability is subject to specific assessment designed to shorten the inter-cycle periods and annual outages as much as possible. The current availability of the JHR Material Test Reactor has been estimated at 190 days, which is similar to the availability of other international material test reactors performing irradiation experiments on materials and fuels.

The JHR Material Test Reactor will be equipped with numerous systems to limit gaseous (e.g. alpha, beta, gamma and tritium emitters) and liquid radioactive releases, as well as the production of solids generated during experiments (gloves, metal structures around experimental devices, etc.).

Most radioactive waste produced by the JHR will result from its R&D activities.

As a nuclear operator, the CEA is responsible for managing this waste. The French Act of 28 June 2006 on the sustainable management of radioactive material and waste governs such issues. Nuclear waste can be very diverse in nature, which is why there are around 160 waste treatment systems on the different CEA centres.

For more information, click on the link below:

⦁ Reports published each year by the CEA: activity reports, financial reports, and reports on risk management (SEE THE REPORTS)

⦁ The report published by the CEA General & Nuclear Inspectorate (IGN) provides their assessment of the nuclear safety of its nuclear facilities and the level of radiation protection at the CEA. Version 2020. (SEE THE REPORTS)

⦁ The nuclear safety and transparency reports (RTSN), which can be consulted on theCEA Cadarache site. These reports summarise the operations of each facility, the volumes of effluent releases into the environment, the radioactive waste produced, and any incidents having occurred. It also describes the monitoring and inspection systems in place. Version 2020. (SEE THE REPORTS)

Operation of experimental devices

Devices for the production of radioisotope

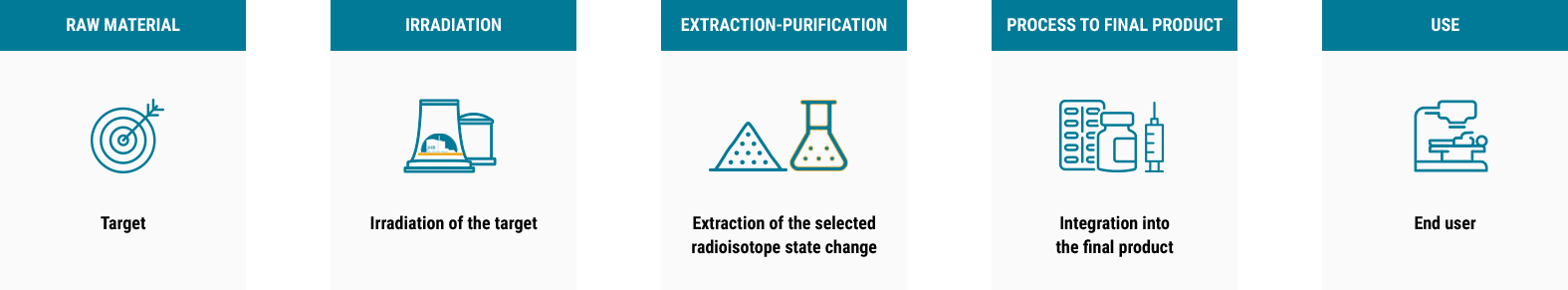

The production of medical radioisotopes relies upon a complex but efficient supply chain that must be highly responsive considering the fact that such radioisotopes have very short half-lives (so they can be quickly eliminated from the body). This supply chain can be described as follows:

1 Procurement of raw materials containing stable or radioactive isotopes

2 Fabrication of specific targets for each radioisotope to be produced. This target can come in different shapes: powder, pellets, disks, etc.

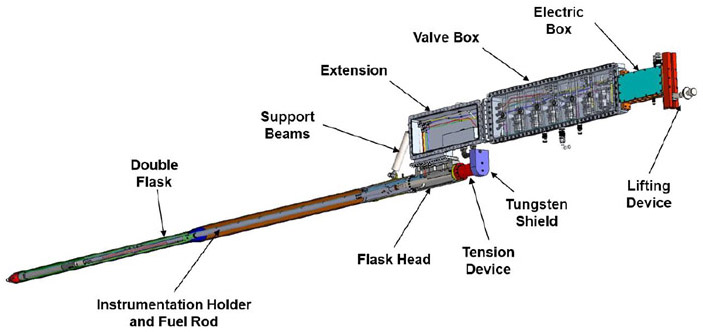

3 Irradiation in the JHR Material Test Reactor:

- The experimenters at the JHR Material Test Reactor put these targets in irradiation containers that are then installed in an irradiation device, itself inserted into the reactor core or reflector

- After irradiation, the experimenters remove the container from the irradiation device and then transfer the targets into a transport cask. This operation is performed either underwater or in a hot cell

- The truck carrying the transport cask leaves the JHR Material Test Reactor to take the targets to a suitable facility where they can be extracted.

4 Depending on the case, the targets may undergo purification after extraction in order to comply with pharmaceutical regulations

5 Their distribution to hospitals follows a complex but rapid system

6 The radiopharmaceutical drugs are prepared so non-radioactive molecules can be added to the radioisotopes making them suitable for diagnostic or treatment in the radiopharmaceutical departments of hospitals

7 Diagnostic or treatment protocols are carried out on patients by the nuclear medicine departments.

The production cinematics of molybdenum-99 illustrate these different stages.