PRODUCTION

OF ARTIFICIAL RADIOELEMENTS

PRODUCTION

OF ARTIFICIAL RADIOELEMENTS

A key issue: the large-scale production of molybdenum-99:

The JHR Material Test Reactor’s main radioisotopes objective is to ensure the European production of 99Mo, used for a wide variety of diagnostic tests in nuclear medicine, such as bone cancer diagnosis. More specifically, this means producing between 25% (representing about 2 billion patients diagnosed) and 50% of European yearly requirements.

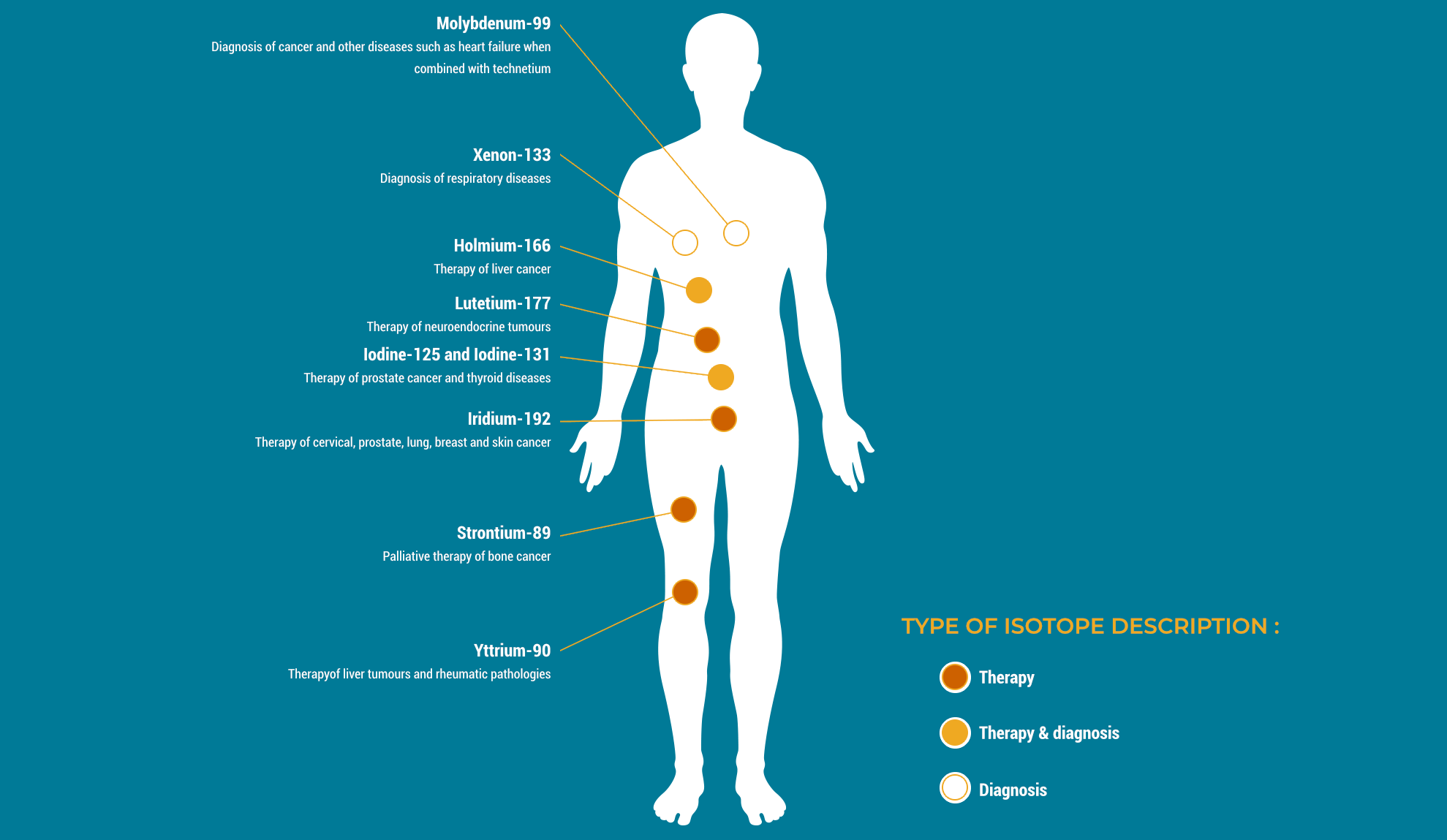

Given these needs in radioisotopes, the JHR material test reactor has the objective of producing the following as soon as it has been commissioned:

• Numerous radioisotope for medical purposes (e.g. 90Y, 153Sm, 166Ho, 169Er, 177Lu, 186Re, 192Ir, 103Pd and 125I, etc.),

• Radioisotope for therapeutic treatments in anticipation of the future developments in this field,

• Radioisotope for the industry and R&D (such as 192Ir, 60Co, 75Se and 169Yb, used for non-destructive testing and equipment sterilisation, etc.).

For instance, certain radioisotopes such as 99Mo are used in medical imaging, e.g. scintigraphy, a functional medical imaging exam that is used to analyse organs and their functions. Others such as 177Lu are used for therapeutic purposes, in vectorised internal radiotherapy, to treat certain types of cancer.

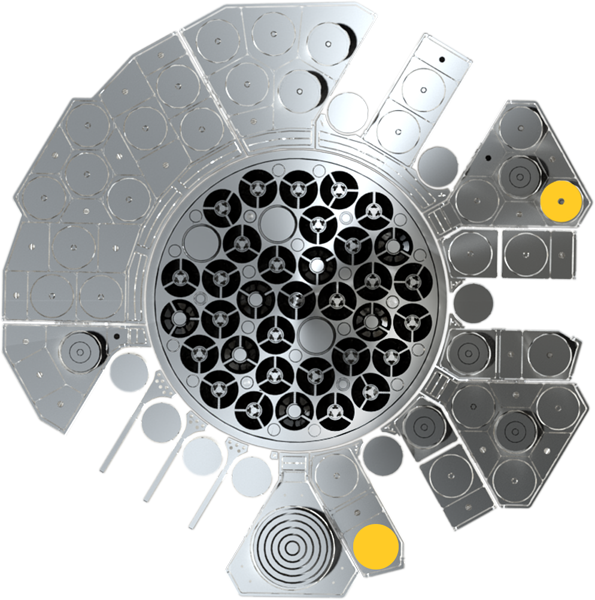

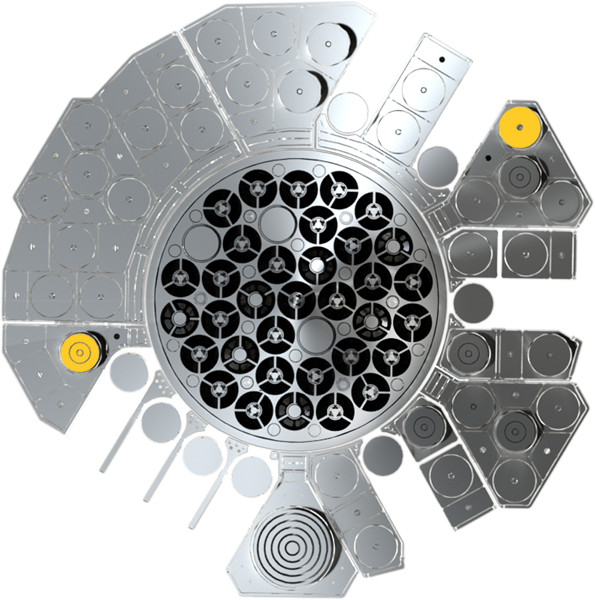

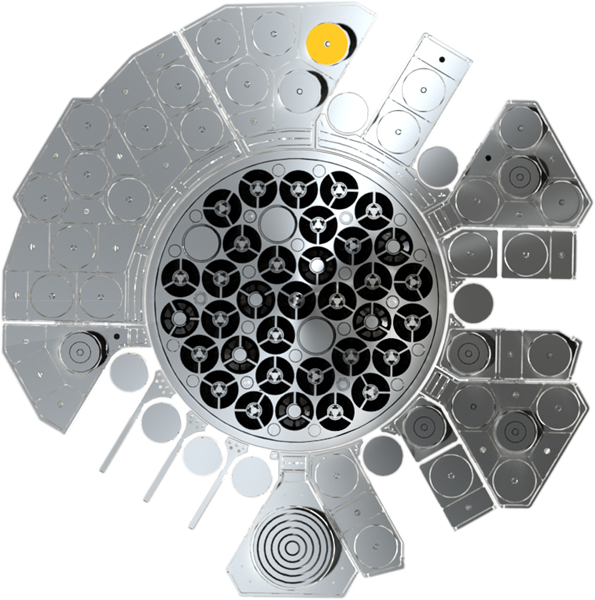

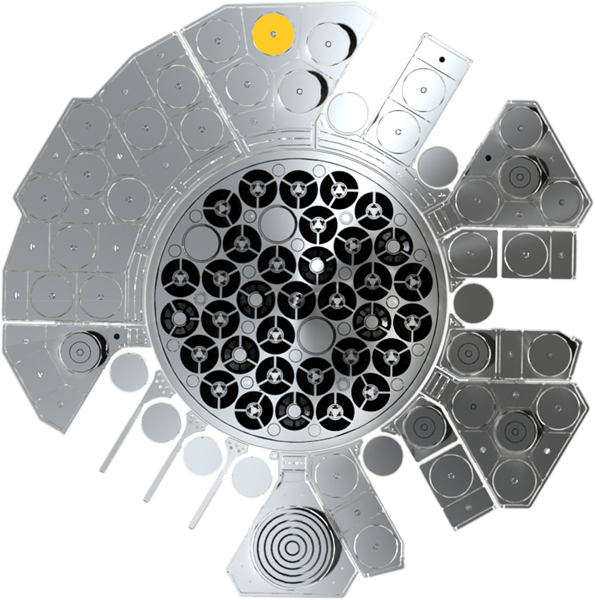

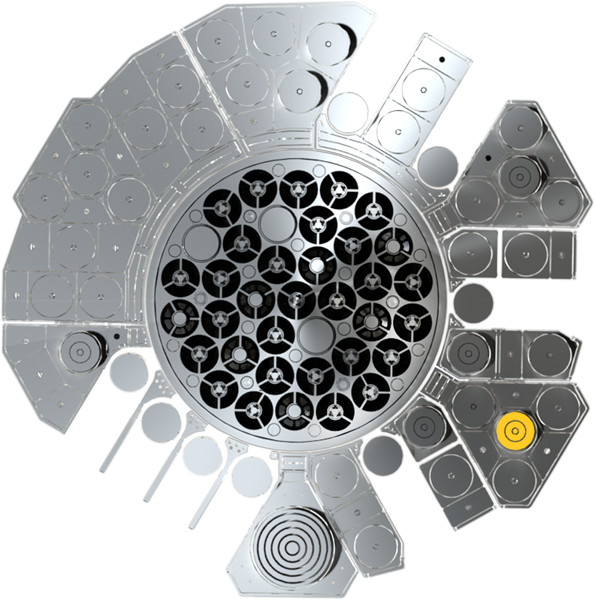

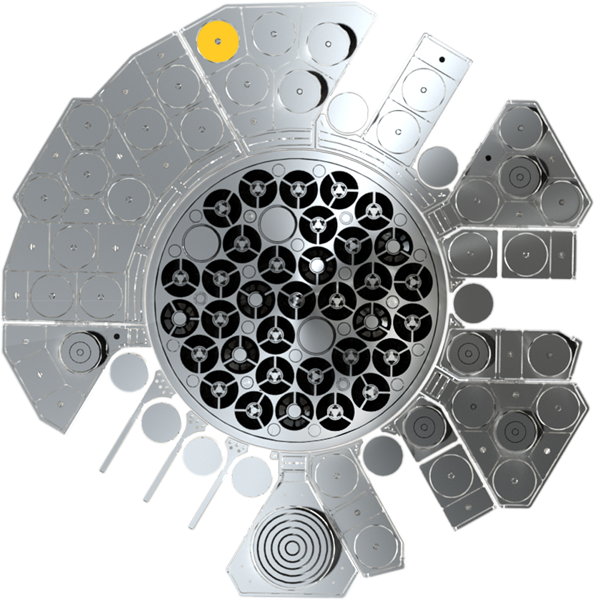

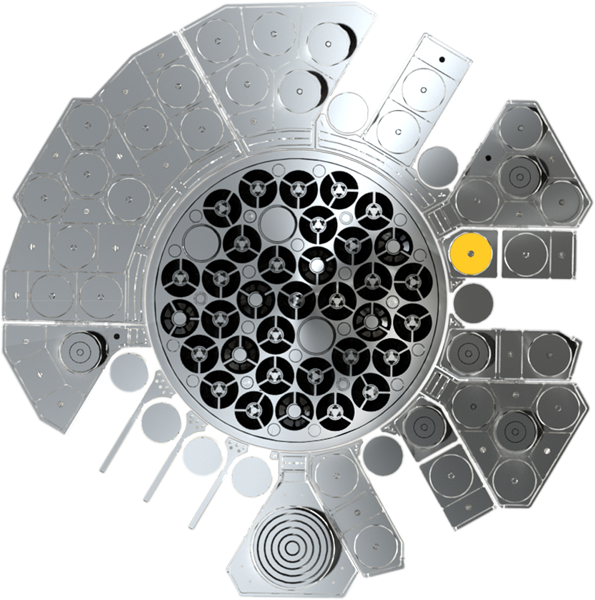

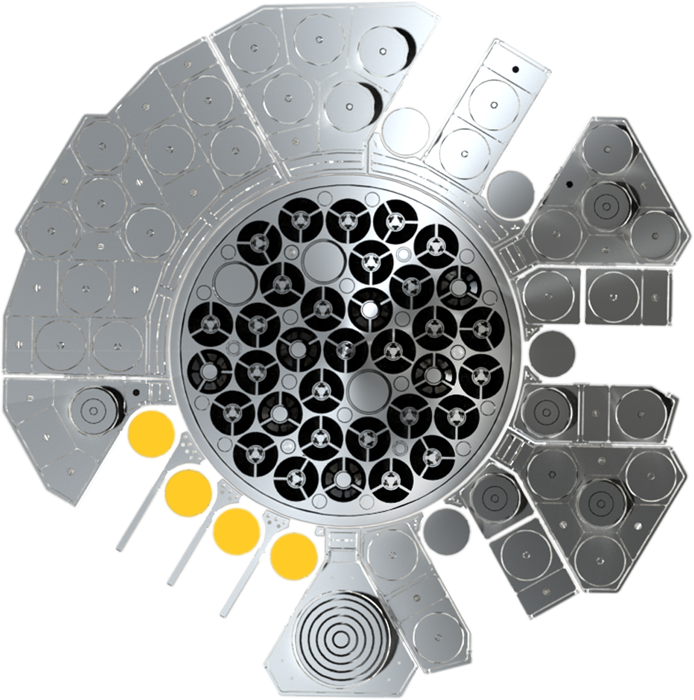

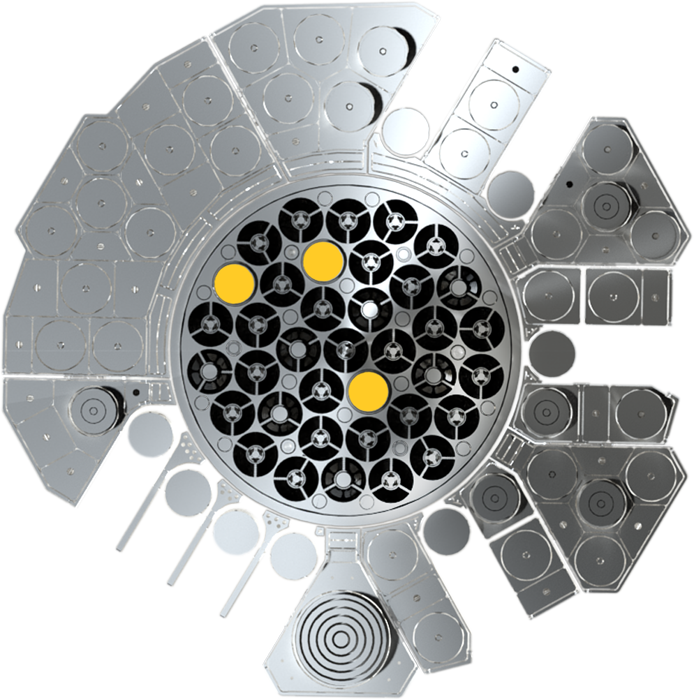

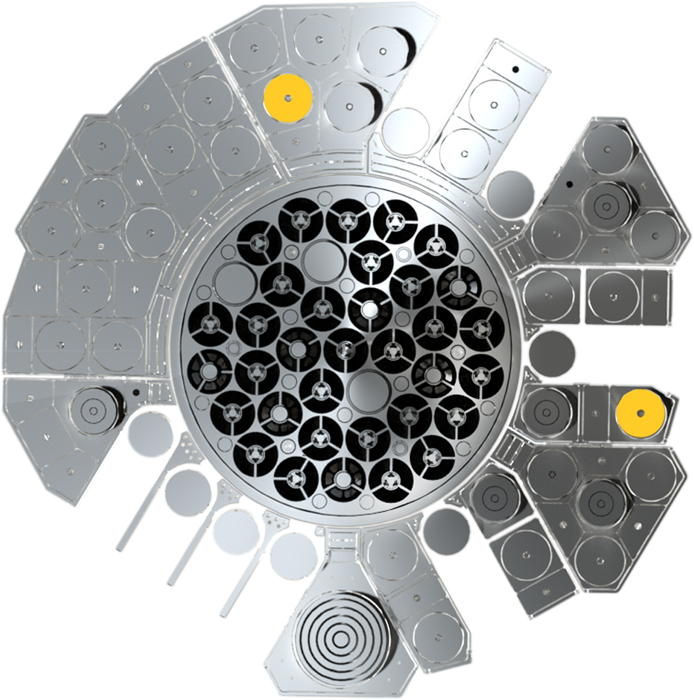

The JHR Material Test Reactor has the ability to produce a very broad range of radioisotope (see diagram below).

RADIOISOTOPES THAT THE JHR WILL PRODUCE

RADIOISOTOPES THAT THE JHR WILL PRODUCE

PRODUCTION OF MOLYBDENIUM

Why 99Mo?

Molybdenium is the most frequently used radioisotope in the nuclear medical sector so it is in high demand.

What is 99Mo used for?

The 99Mo, after decaying through a generator produce 99Tc. The technétium is an important marker in scintigraphy, and is used in 70% of all nuclear medicine diagnoses, i.e. around 40 million protocols/year around the world.

Advantages:

• Chemistry conducive to producing radiopharmaceutical drugs

• Mono-energy element (140 KeV), particularly suitable for gamma cameras (22,000 cameras in the world)

• Short radioactive half-life (6 h), thus little radiation exposure

• Inexpensive

Properties :

The radioactive decay of 99Mo results in the production of 99Tc.

Duration of irradiation in the JHR Material Test Reactor: to be defined

Radioactive half-life: 6 hours

99Mo and the JHR:

The JHR Material Test Reactor is relying on the substantial production of 99Mo. Due to the complexity of its production and the unique structure of the JHR Material Test Reactore, the equipment needed to manufacture this radioisotope has been specially developed, produced and assembled in parallel to the construction and assembly of the JHR Material Test Reactor.

PRODUCTION OF IRIDIUM

Why?

Iridium can only be produced in reactor conditions, with multiple applications in different markets and hence a broad customer profile.

What is 192Ir used for?

192Ir is currently used by the industry as a source of gamma rays for industrial radiology to locate defects in metal components. It is also used in medicine for radiotherapy, particularly brachytherapy

Advantages :

It is not very complex to produce and has a relatively long half-life, which means it can be used for extended periods worldwide.

Properties of 192Ir:

Duration of irradiation in the JHR Material Test Reactor: ~25 to 40 days

Radioactive half-life: 74 days

192lr and the JHR:

192Ir can also be produced in MOLFI irradiation devices or in other devices.

PRODUCTION OF LUTETIUM

Why 177Lu?

This medical radioisotope is providing new hope for the treatment of prostate cancer, which is responsible for 90,000 deaths per year in Europe. According to the latest clinical studies, the demand for 177Lu to treat prostate cancer has been growing.

What is 177Lu used for?

This radioisotope is currently used in hospitals to treat neuroendocrine cancers, which mainly affect organs of the digestive system, i.e. the stomach, pancreas and intestines. The therapeutic radioisotope 177Lu is looking to become a promising path for prostate cancer treatment.

Advantages:

One opportunity could be to set up a radiochemistry laboratory for the chemical extraction of 177Lu, with a view to producing lutetium chloride and thereby shortening the time scales between irradiation and integration in the final product.

Properties of 177Lu:

Duration of irradiation in the JHR Material Test Reactor: 6 days

Radioactive half-life: 6.5 days

Production of this radioisotope requires suitable equipment for irradiation, insertion, extraction and reconditioning to ensure the necessary responsiveness to produce just in time.

177Lu and the JHR:

The production of this radioisotope calls for investment to develop an effective production procedure on an industrial scale. The JHR Material Test Reactor is currently studying the possibility of implementing such a system in the facility.

LARGE-SCALE PRODUCTION CAPACITIES

The JHR Material Test Reactor is developing equipment that can be used to produce multiple radioisotope to be very responsive in terms of production, whether small or large volumes, or radioisotope with both long and short half-lives.

For radioisotope with very short half-lives, it will be necessary to optimise the duration of irradiation operations, underwater transfers of containers/ devices to the hot cells, and in-cell post-irradiation operations to ensure that clients have sufficient time for the post-processing of targets.

The teams are currently studying the possibility of using a transfer system from the irradiation positions to a shielded box in which the irradiation containers could be removed and the capsules could be transferred into the transport cask. This system would have the advantage of saving time with respect to the length of post-irradiation operations, while freeing up the reactor maintenance equipment and a hot cell.

For this reason, JHR Material Test Reactor teams are studying the possibility of producing other medical radioisotopes that could find outlets on promising or developing markets, as well as for new industrial applications.