CLOE

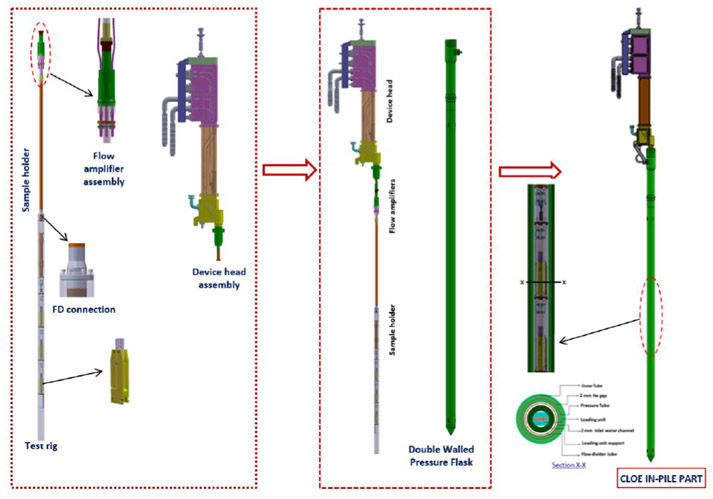

The purpose of the CLOE device is to study IASCC in the structural materials of PWRs and BWRs. In some reactors, it appears that some connecting components in the primary system, more specifically the core baffle screws, were failing during maintenance operations. The CLOE loop will be used to conduct integral tests so as to reproduce such complex phenomena. Typical tests planned are slow-strain tensile tests, constant load tests and crack propagation tests, so the loading module should be designed to apply dynamic loading to the test samples.

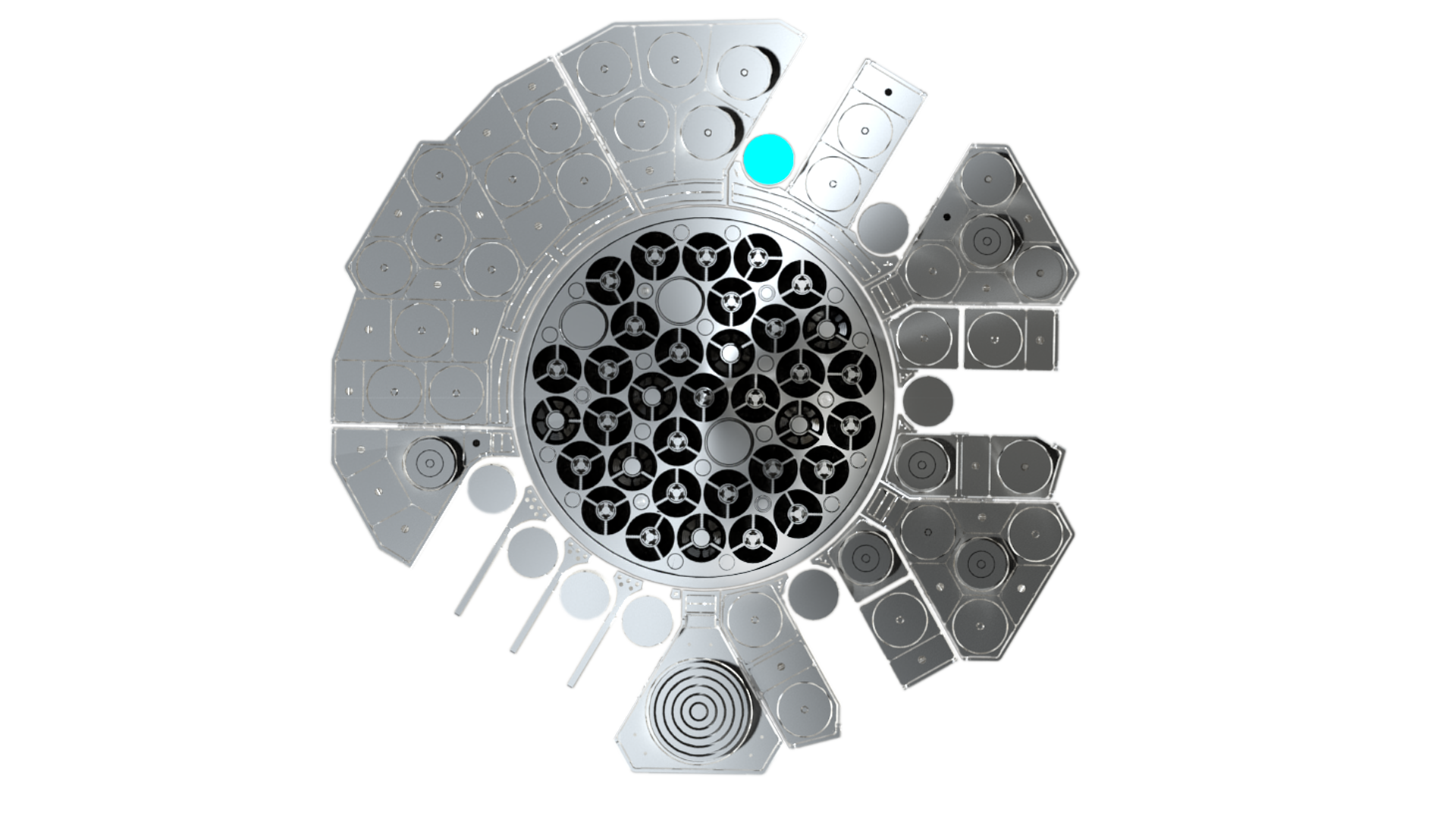

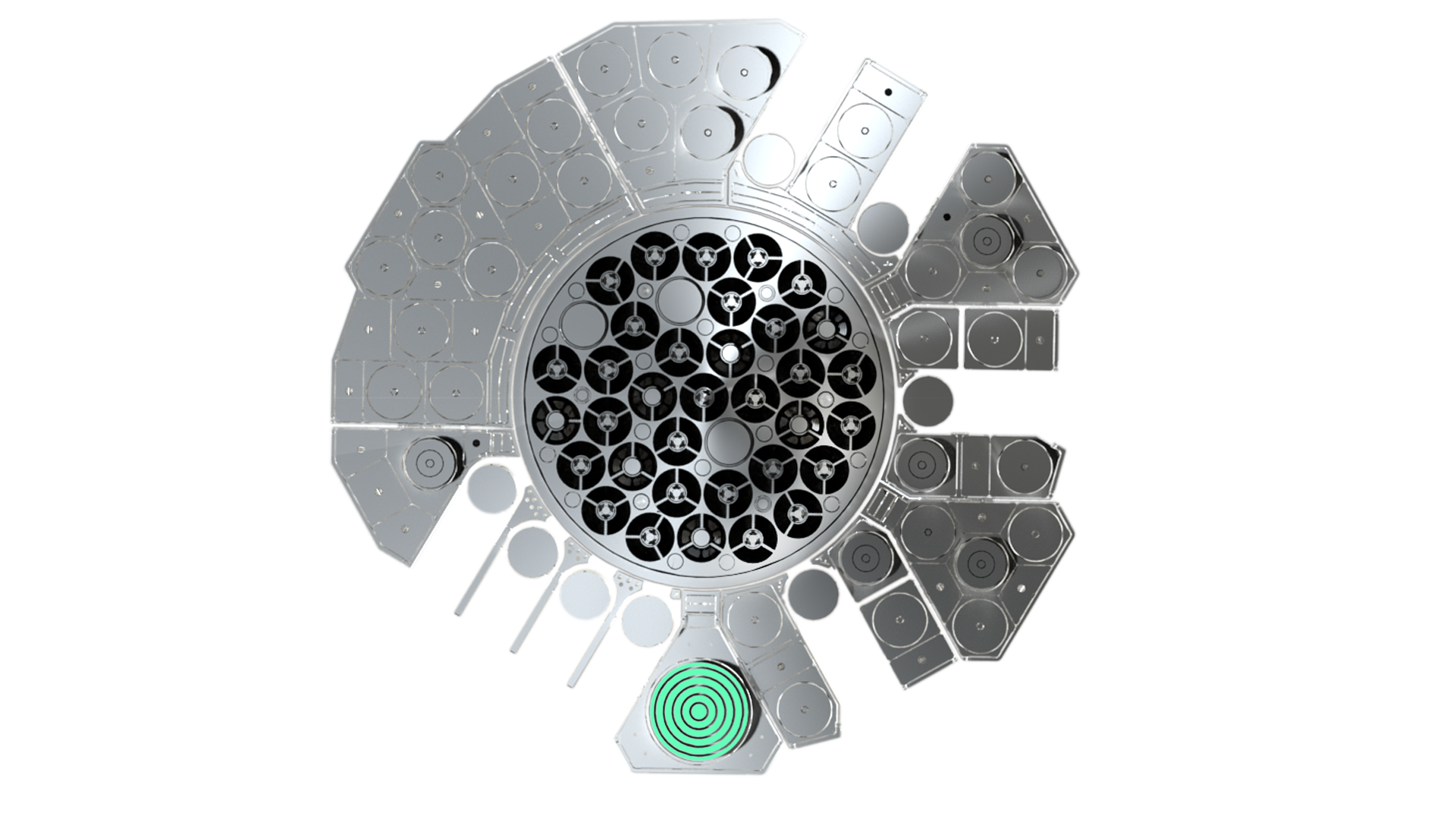

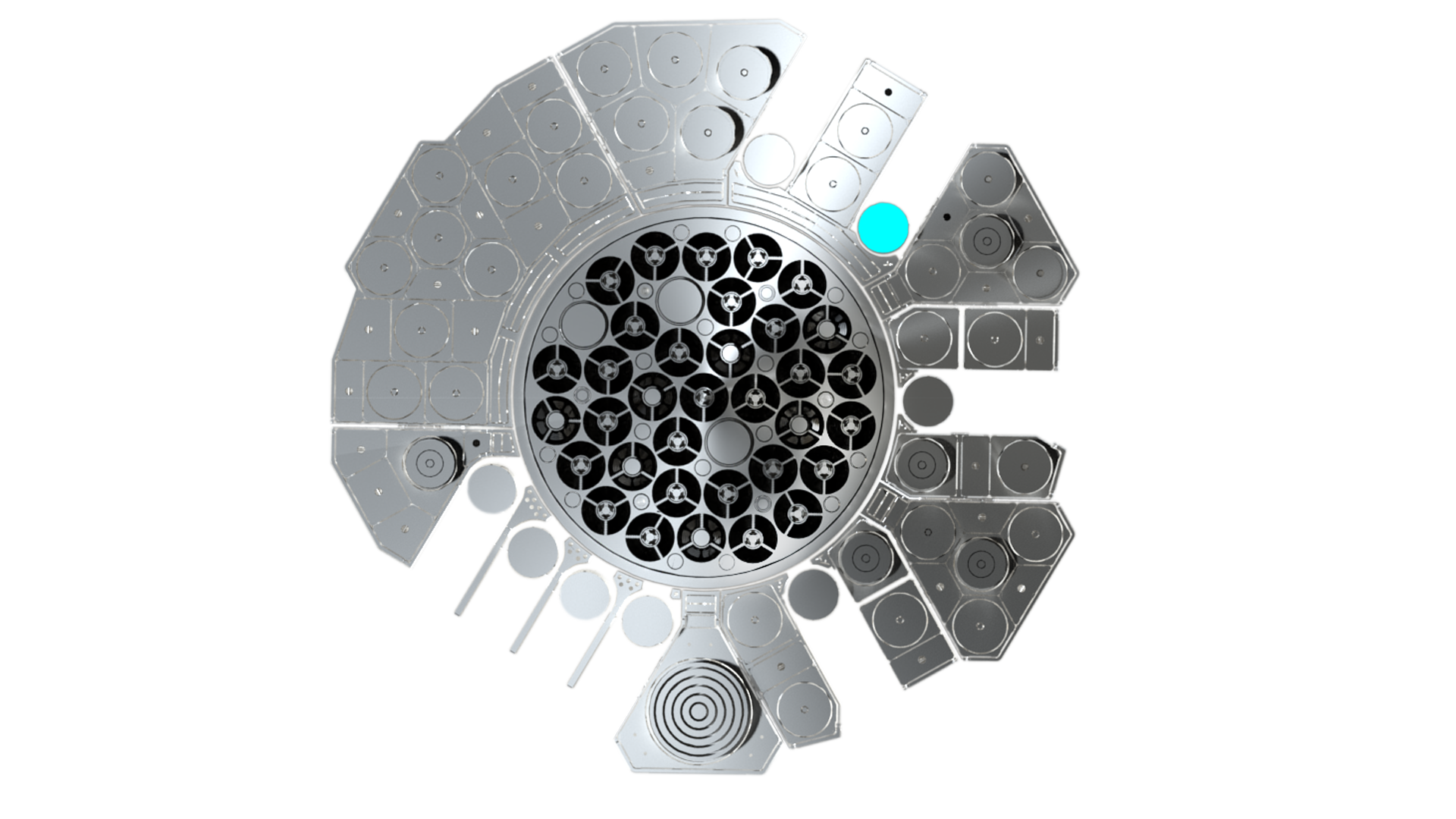

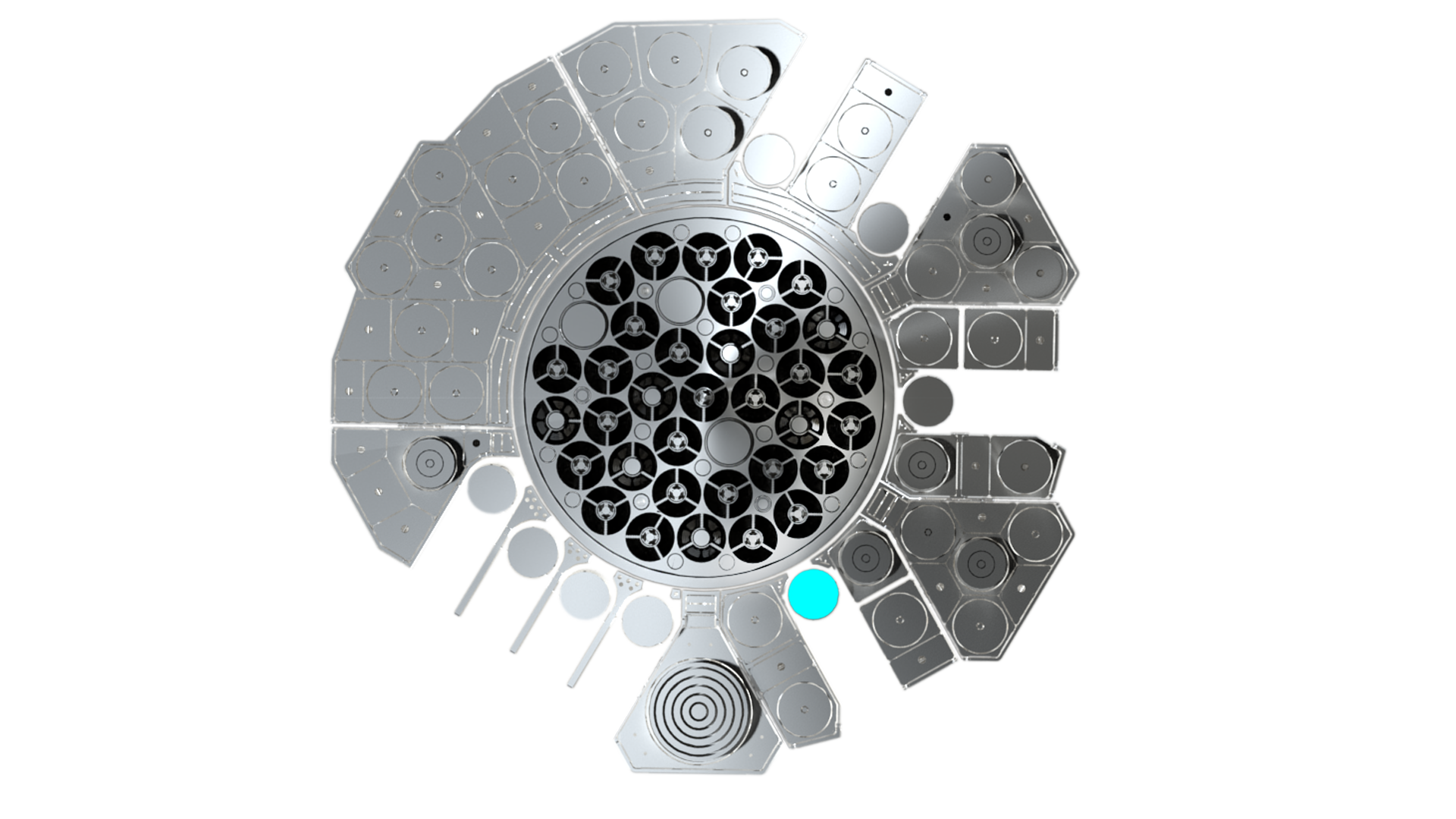

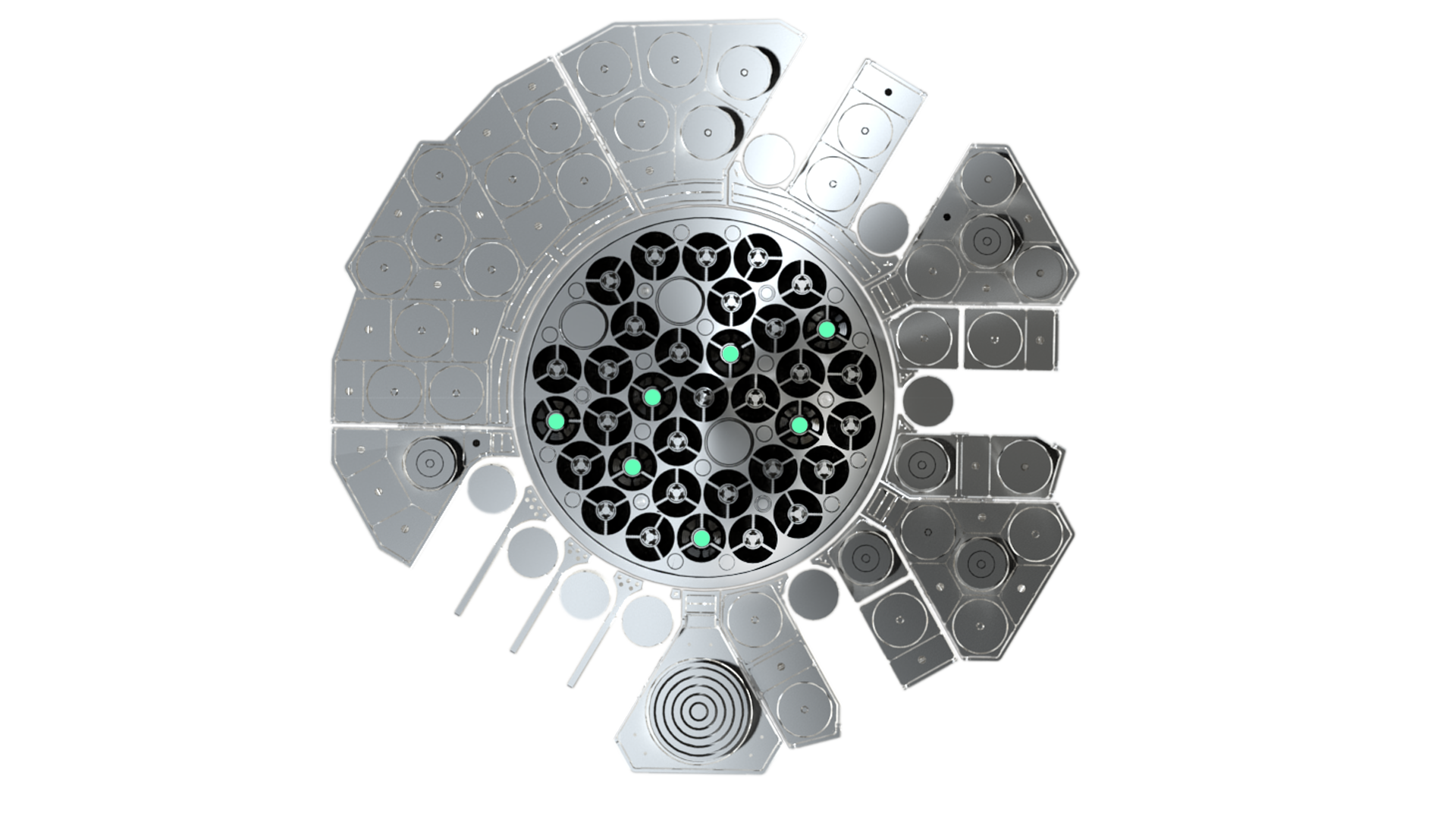

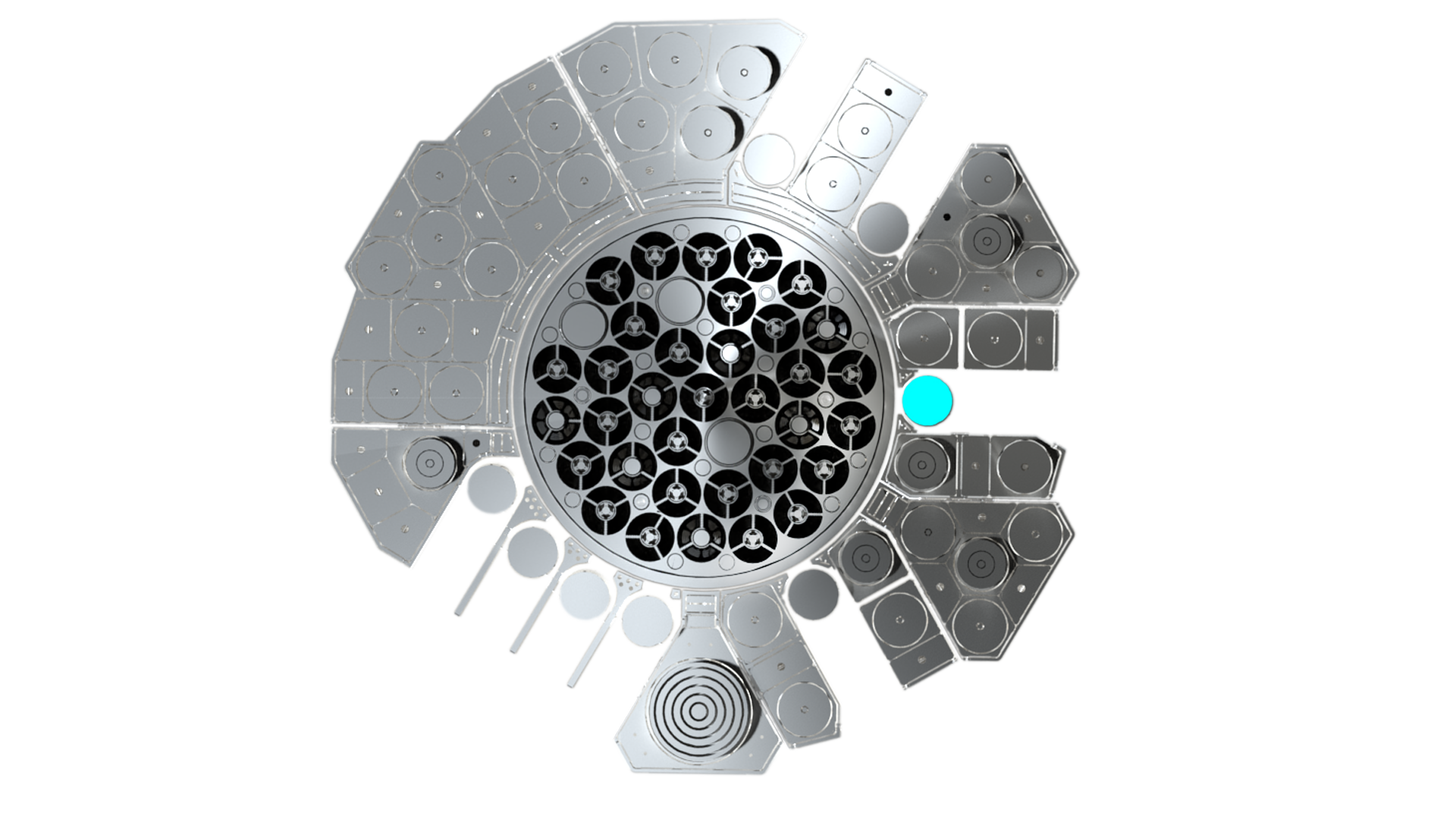

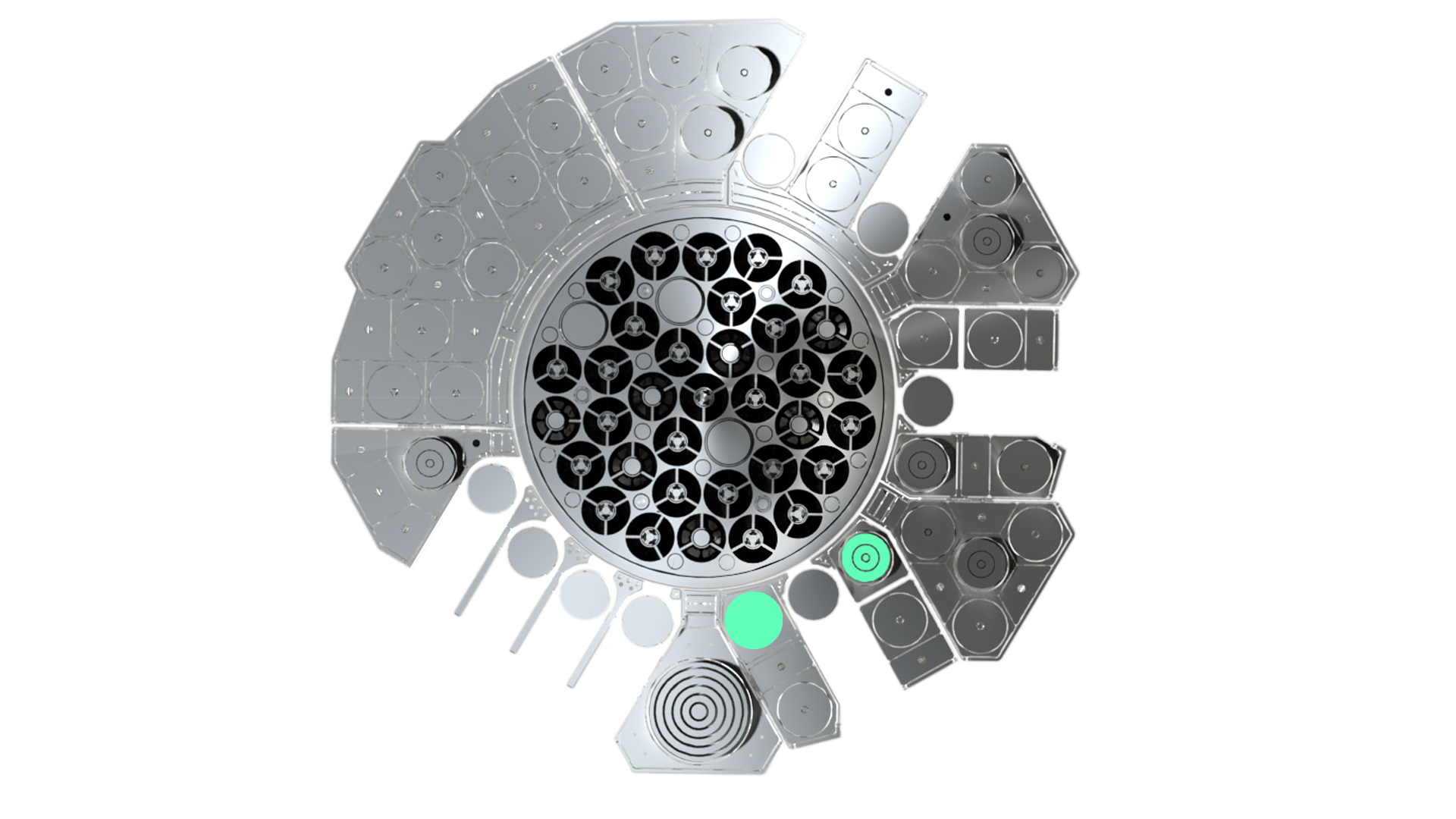

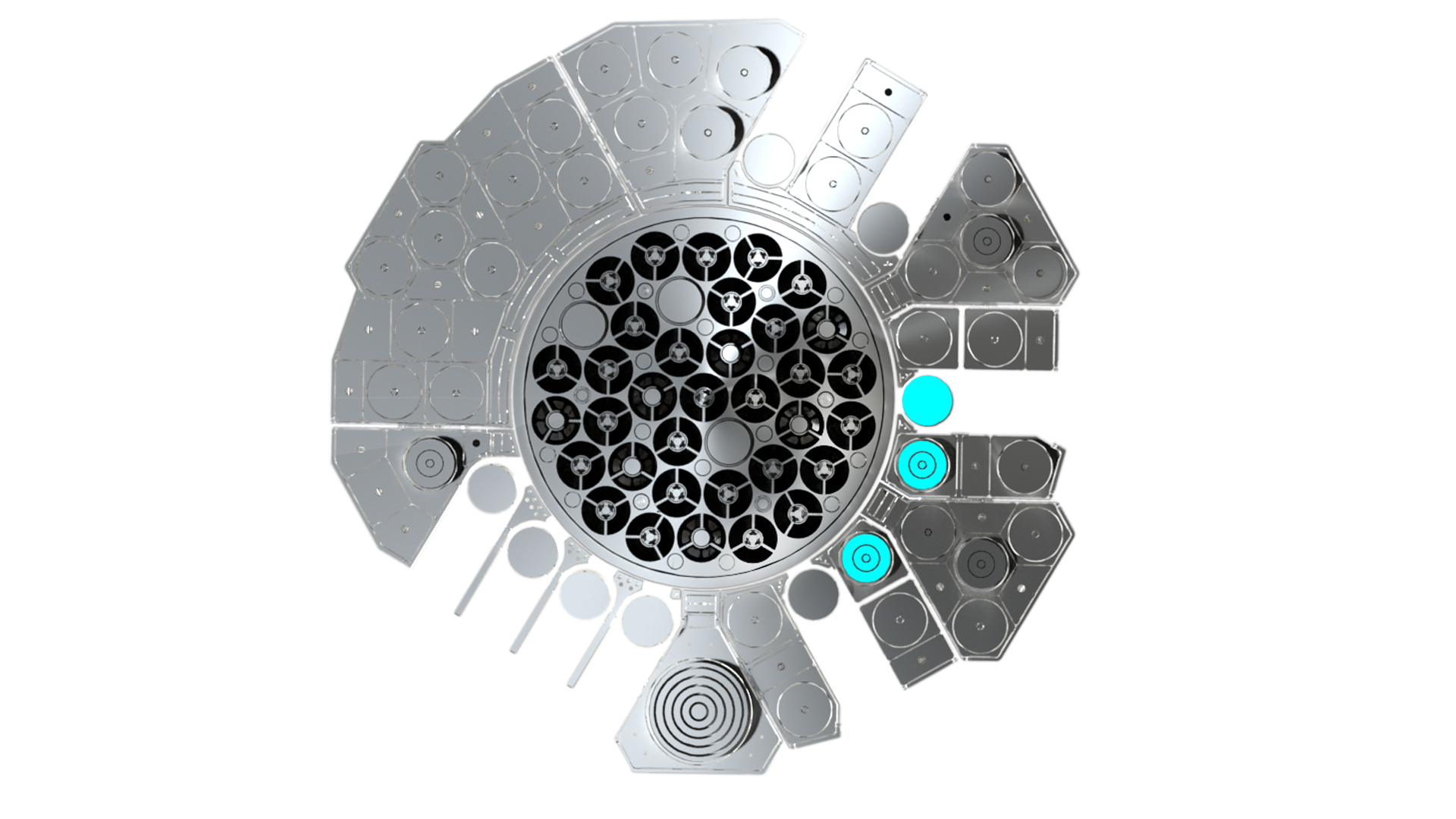

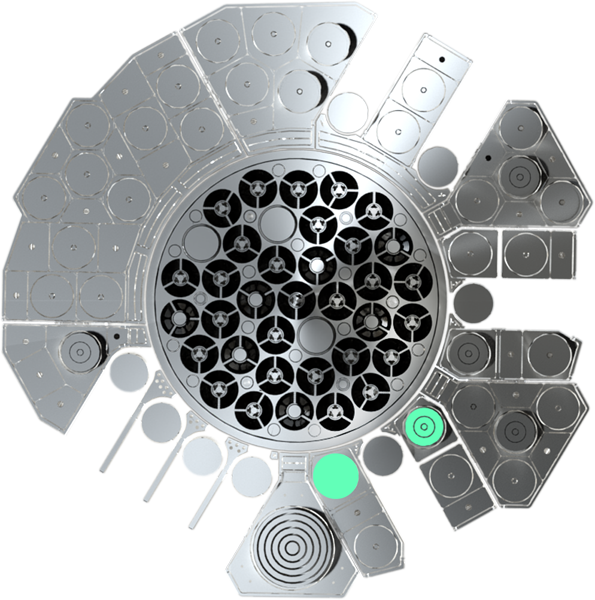

The in-core part of the device will be placed in the reflector in a fixed position, connected to a process loop located in an experimental cubicle.

During irradiation, the sample holder is designed so mechanical loads can be applied to fresh or pre-irradiated samples, associated with in situ measurements, including electrochemical and crack growth measurements. Out-of-core Stress Corrosion Ccracking (SCC) tests will also be performed in a specific autoclave in the CLOE cubicle.

The main design parameters of the CLOE loop are given below:

■ Location in the JHR Material Test Reactor reflector

■ Sample holder designed for:

• Crack propagation as a conservative safety case for designing the loop

• Pre-irradiated test sample

• 3 CT samples mechanically loaded with pressurised bellows

■ Neutron characteristics:

A best estimate at the maximum flux plane, 100 MW, 27% 235U, and the core at equilibrium in mid-cycle

■ Sample temperature:

• 300-360°C for PWR conditions

• 260-290°C for BWR conditions

• Controlled temperature of ±3.5°C in the effective area of each sample

■ Design pressure: 210 bar, maximum operating pressure: 190 bar

■ PWR water chemistry environment

■ BWR water chemistry environment

■ Instrumentation

In-core

• DCPD measurements, spot-welded to the CT arm extensions

• Temperature measurements: coolant inlet, coolant outlet, CT samples

• Electrochemical corrosion measurements

• Activation dosimeters

Out-of-core

• Temperature, flow and pressure measurements at suitable locations

• Water chemistry monitoring: dissolved hydrogen, dissolved oxygen, specific conductivity, pH measurements, and offline measurements through sampling.

The JHR has been designed with a full set

of experimental devices making

it possible to conduct the experiments

needed to characterise,

select and qualify new fuels and materials.

Some of these experimental devices

are capsules while others are loops,

which makes it possible to adjust

the experimental conditions in real time

to obtain even better results.