Industrial safety & the environment

The health and safety of its employees, contractors and partners involved in its construction and commissioning activities is a top priority at the JHR Material Test Reactor site. Preventing accidents, injuries and ill health while protecting the environment is one of the JHR Material Test Reactor’s primary concerns. This is why the construction and commissioning work has and will continue to be carried out under the safest possible conditions.

All contractors on the project, including the CEA, have signed the industrial safety policy and are committed to making safety their main priority.

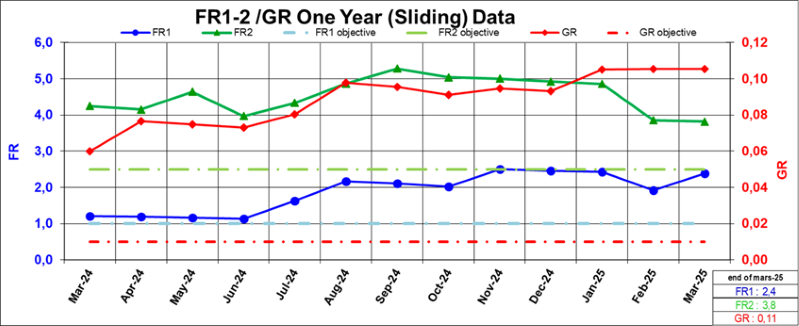

The JHR Material Test Recator project monitors its monthly indicators

Industrial safety indicators

On August the 12th 2024

559 days

without any work accident

Since 1st January 2023, the JHR project is now focused on the number of accidents with and without lost time, with a record of 253 days.

• FR1 (accident frequency rate 1): this industrial safety performance indicator defines the number of occupational accidents with lost time over a 12-month period per million hours worked

• FR2 (accident frequency rate 1): this industrial safety performance indicator defines the number of accidents with and without lost time over a 12-month period per million hours worked

• GR (severity rate): this industrial safety performance indicator defines the ratio between the number of days lost multiplied by 1,000 and divided by the number of hours worked over a 12-month period.

Improvement actions

⦁ Industrial safety behaviour inspections

The JHR Material Test Reactor project has implemented informal inspections to observe industrial safety behaviour in the workplace.This involves observing employees (JHR Material Test Reactor project personnel and contractors) ‘in the field’ to find solutions to improve occupational safety and the working conditions.

Employees are asked to think about the situation themselves so they can resolve their own industrial safety issues and improve their workplace conditions.This approach actively engages employees in the implementation of actions that have been decided together.

At the end of December 2022, a total of 65 inspections were carried out in 2022, with 229 good practices observed, 5 hazardous behaviours observed, and 96 hazardous behaviours corrected.

⦁ JHR Industrial Safety & Environment Day

Industrial Safety & Environment Day was celebrated on October 4th 2022 in the JHR Material Test Reactor project offices and on the construction site. In 2022, this day the work package contractors currently operating on the construction site have ensured the organisation of some workshops (electrical risks, mechanical handling, scaffolding).

As every year, many items have been selected to help staff better understand the risks and how to work in safe conditions at all times, some have been renewed (road risk multiple choice questionnaire, national gendarmerie awareness, handling of fire extinguishers), some were new (management of conflicts, theatre, safety buzz) :

Activities on how to develop well-being and a healthy working lifestyle have still been very appreciated and attended (yoga to reduce stress, seated massage, breathing exercises).

Environment has also been addresses with carpooling, electric means of transport workshop and an Escape Game focused on this thematic.

⦁ Company industrial safety trophy

In 2022, four company industrial safety trophies were awarded to companies at the inter-company general assembly on health, industrial safety and work conditions (CISSCT) for :

⦁ Implementation of good practices ;

⦁ Deployment of new industrial safety initiatives ;

⦁ Ownership of industrial safety issues.

These trophies have been awarded:

⦁ For the 1st quarter : EQUANS (lot D08) ;

⦁ For the 2nd quarter : MAINCO (L05/L13) ;

⦁ For the 3rd quarter: CLEMESSY (E01) ;

⦁ For the 4th quarter : ONET Propreté Service (L11).

⦁ Employee of the month

In 2022, every month an employee received congratulations for:

• Their involvement in industrial safety (wearing personal protection, not observations reported over the past 3 months, good dialogue and suggestions to improve industrial safety, team cohesion, etc.) ;

• Compliance with the industrial safety rules ;

• Ability to come up with new ideas and take initiative within their remit.

Project challenges and objectives

Project challenges and objectives

As with any project, construction of the JHR Material Test Reactor is managed in such a way as to make sure the objectives are met in terms of scheduling, costs and management of risks and opportunities.

The Project Control Department within the JHR project management division is in charge of:

• Managing the schedule by involving all parties concerned in the activities ;

• Overseeing the execution of risk analyses and ensuring the implement of prevention and mitigation plans (monthly steering meetings with action plans to reduce risks and creating working groups to focus on critical points) ;

• Tracking, budgets and cost estimates up to the end of project completion ;

• Defining and monitoring the project indicators (weekly monitoring of usual project indicators: physical progress, non-conformity reports, design change reports, etc.) ;

• Overseeing the resolution of remaining open points ;

• Ensuring internal oversight using project management tools based on visual performance management.

JHR project values

To bring together the teams from the different stakeholders involved in this project, as well as to create a common identity, the project management has defined the following core project values:

Always make nuclear safety and industrial safety the priority

Be honest

Obtain results

Promote team work